It's a potent and fragile sorcery.

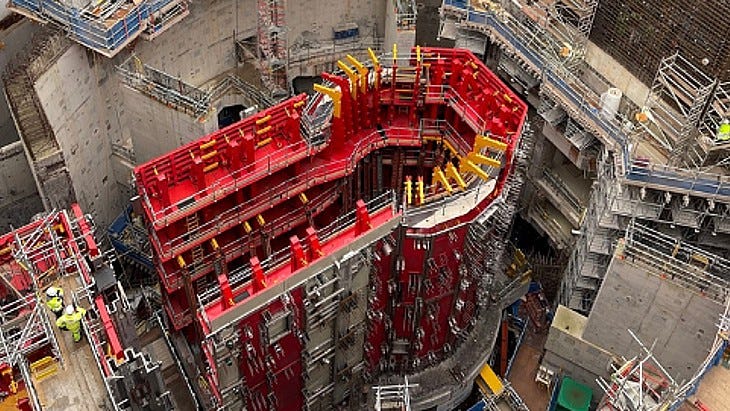

A forest of spires and beams rise over Hinckley Point C, a vast construction jungle. Over it a giant dome is lowered, like some industrial age flying saucer. It casts shade like the throwing of fate, and slowly descends…

This is the majesty and pain of nuclear birth pangs, but these days they're too few, and too expensive by half. What happened, and how do we prevent the nuclear revival from becoming stillborn?

Recently the British government broke the habit of a lifetime and actually Made A Decision, clearing the Sizewell C nuclear plant for construction, committing 2.5 billion to a prototype fusion plant and announcing Rolls-Royce as the winner of the UK Small Modular Reactor competition.

But big words demand big deeds, and His Majesty's Government has excellent form in procrastination. If there was a world championship they'd be a shoo-in, but they'd have to think carefully about entering.

Anyway, on the face of it all is good in nuclear news, which in a world of pricey energy and climate commitments is the best kind of news to get. But it needs to be cheaper than it was last time.

The British Hinckley Point C nuclear power plant, featuring two French EPR reactors with a combined capacity of 3.2 Gigawatts, is set to be the most expensive nuclear plant in the world. It could hit a cost of £46 billion, which is simply monstrous, and that kind of financial performance salts the ground for everyone who follows and makes new nuclear hard to swallow.

This is a shame, because apart from countries with abundant hydropower resources, nuclear energy is really the only runner when it comes to zero carbon baseload generation. It's expensive, but that cost is almost all up-front, which is a big dose of salty honesty in a world full of sneaky financial sweeteners. It'd almost be admirable if it wasn't so damned steep.

…Except, it doesn't have to be.

China builds them cheap. Korea builds cheap. The United Arab Emirates built cheap. All use well-proven, well-tested reactor designs with global recognition. It feels like we're missing a trick here, and it's one that we can't afford to miss, stuck between the descending rocks of energy security and the immovable boulder of climate change & emissions reduction. Nuclear energy is the only real lever available that will let us wriggle out of that impossible squeeze.

And let's be clear, a lot of our wounds are self-inflicted: Political hand-wringing, endless re-designs of proven platforms, the bizarre concept of there being ‘no safe level’ of radiation… and of course the UK's own insane planning and approvals bureaucracy. We've sure tried to stop ourselves from ever building anything, anywhere.

But I don't want to talk about that. Here we're going to go through some of the technical ways of reducing nuclear build costs. Techniques that will work in any country, anywhere.

So, what say you: Are you ready to Make Atomics Great Again?

1: Steel bricks.

Construction is chaos.

That's what it looks like from the outside, anyway: Barely controlled and very expensive chaos. Lots of bodies, lots of heavy kit. Lots of just-in-time arrivals and the possibility for delay. Rare metal dinosaurs rear up over the build site, like Big Carl, a colossal 250 metre tall crane capable of lifting 5,000 tons: A high-risk delivery in any schedule and a project in its own right.

This is the sharp end of a nuclear power project. The build phase on deployments like this is where the largest amount of money is spent, at the highest rate, doing the largest number of things with the most people, all at once.

Anything you can do to de-risk it, simplify it or speed it up is priceless.

Enter ‘Steel bricks’.

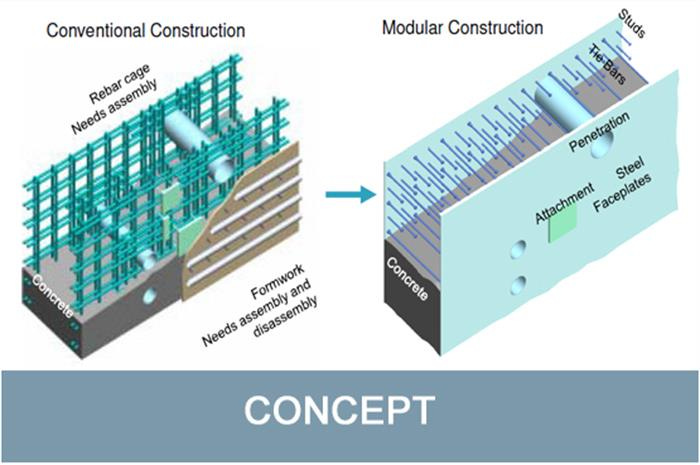

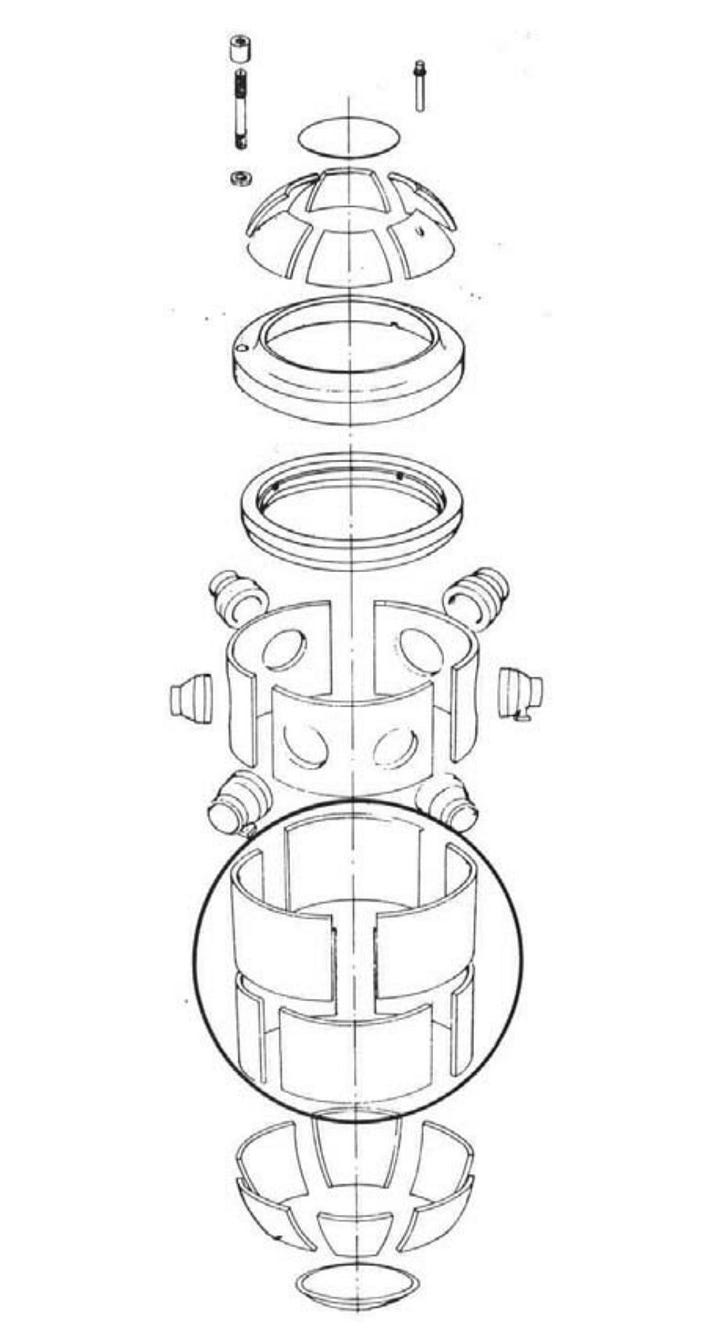

Steel bricks, or Steel-Concrete-Structures (SCS), are a way to modularize civil works of buildings, nuclear reinforced concrete structures and so-on in order to accelerate construction. They are large pre-fabricated hollow frameworks of steel in a torsion box structure with reinforcing cross-beams. The idea is that they can be swiftly positioned on-site in an interlocking framework, then filled with concrete; when the concrete dries around the stiffening beams then Hey Presto! -you have a reinforced concrete structure.

This disarmingly simple trick aims to shorten construction times and should demand fewer people, and fewer steel rebar sections, on-site at any one time. Fewer queues, fewer jams, easier to organize… you can see the efficiencies stacking up already, but the SCS prefabrications themselves are not cheap. For a start, they need to be built sturdy, sturdy enough to hold together under their own strength before the concrete pour and during lifting operations on-site, which means you need more steel. It’s also, frankly, easier to supply trucks full of concrete and flatbeds piled high with rebar than it is to design & build massive pre-fabricated modules in a factory somewhere.

So why do it?

Speed and simplicity of construction is the goal! Because you don’t have to painstakingly build complex rebar structures on-site, there’s less room for error and a lower requirement for on-site riggers, builders and engineers in an already congested location. This means things can speed-up, and time is money.

Time is a lot of money in nuclear. Not only can the construction phase be a monster itself, as evidenced by dinosaurs such as Big Carl, but the high up-front cost and long lead time of new nuclear builds means that a clear majority (almost two thirds) of the cost of nuclear generation is from capital interest on the money needed to build it in the first place.

Which is a bit sickening. We’re leeched by the money men, again.

But what that means in practice is that anything that can speed up a schedule and reduce the time between financing and generation directly reduces the cost of nuclear power.

Time is money. Remember, the burn rate of a big nuclear project can easily be millions or tens of millions a day.

EDF, the French electricity company, which has a strong hand in the nuclear business, has been experimenting with SCS construction for some time, and no wonder: French nuclear plant designs, though undoubtedly formidable, have acquired an unsavoury reputation in Europe as being brutally expensive in recent years, and anything that can reverse this trend is welcome.

Surely, though, concrete bricks can’t be worth that much, can they? You’d be surprised.

Modelling on generic large reactor and Small Modular Reactor (SMR) projects has shown that using pre-fabbed steel brick construction on the nuclear island can save massive 6%-8% of total cost on large reactors, which when you consider the bank-breaking 46 billion-quid pricetag of a monster like Hinckley Point C, is well worth chasing. Fail to tackle this and we might as well resign ourselves to turning off the washing machine whenever the wind stops blowing. A grim future indeed, and a smelly one.

For petite SMR reactors the steel bricks are only expected to be worth 3% of cost, however, which is a puzzle, until you consider that for SMRs the proportion of effort devoted to civil works is simply a lot lower, meaning that there’s less for steel bricks to do. SMRs have their own problems, which we shall visit in due course.

And of course, remember that civil works are not the only big budget part of a nuclear new build, or even the lengthiest. You still need to install equipment, commission it, test it and so-on, but all of this effort first depends on having somewhere to commission and test it in. Construction provides this, and is a critical path for the project, so the faster the better.

Chop-chop! Lay those bricks.

2: Advanced Welding.

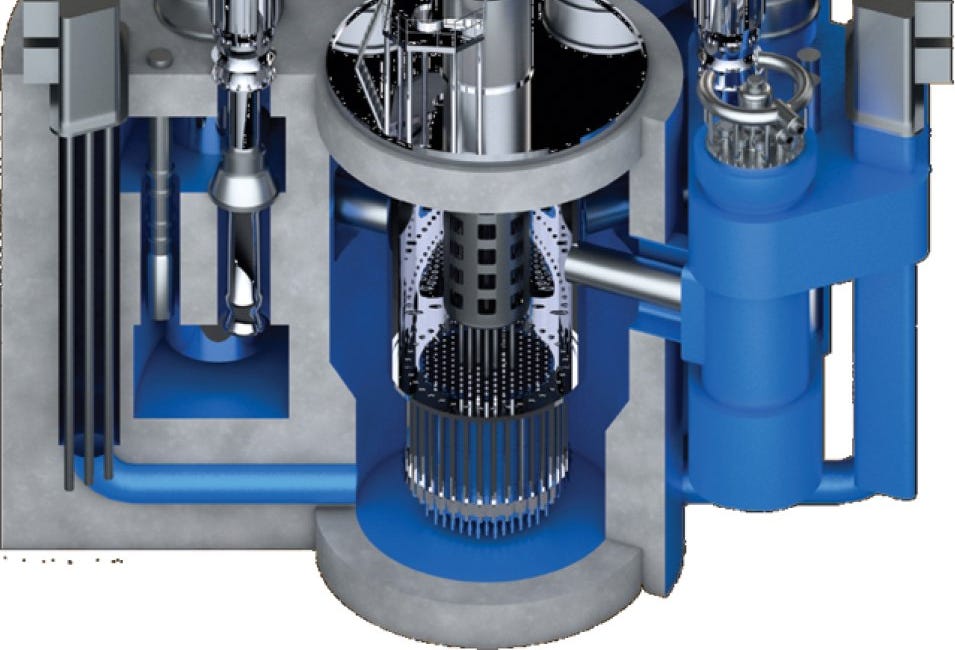

Behind the scenes of any new nuclear project is a big fabrication effort: Gigantic pressure vessels need to be forged, machined, assembled and welded together, like the Lego set of titans. They need heat treating, testing and inspection. It’s big work, seldom carried-out and difficult, and that leaves a lot of reactor architecture on the long finger of extended lead times, in stretched supply chains that can only do so much, so quickly.

But a lot of the big units do need something in common: They all need to be welded.

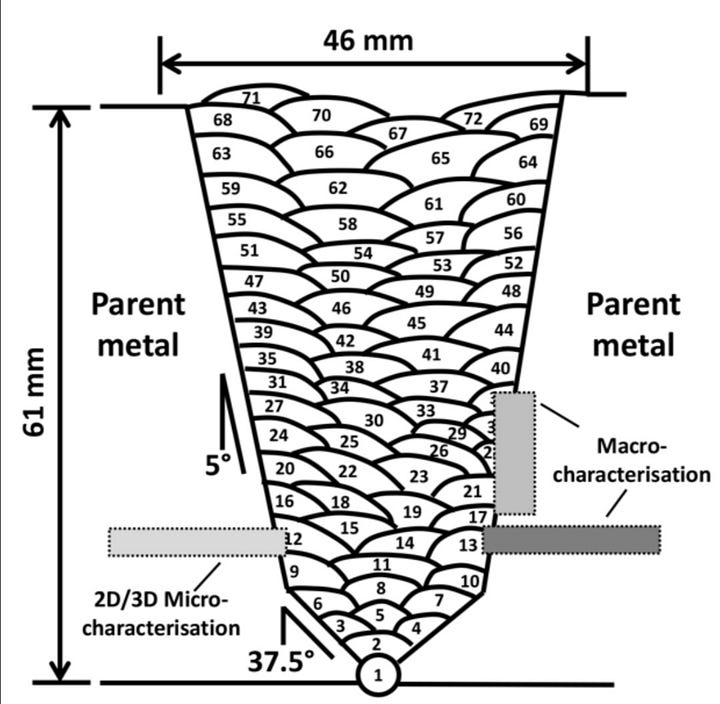

There are a number of advanced welding developments currently leaping through the nuclear sector, each promising to radically reduce fabrication times, and by a lot: A reactor pressure vessel, the stolid steel heart of the nuclear dragon, can spend up to a year being welded, a figure which blows any normal person’s mind all over the nearest wall.

How the hell do you spend months just welding something!?

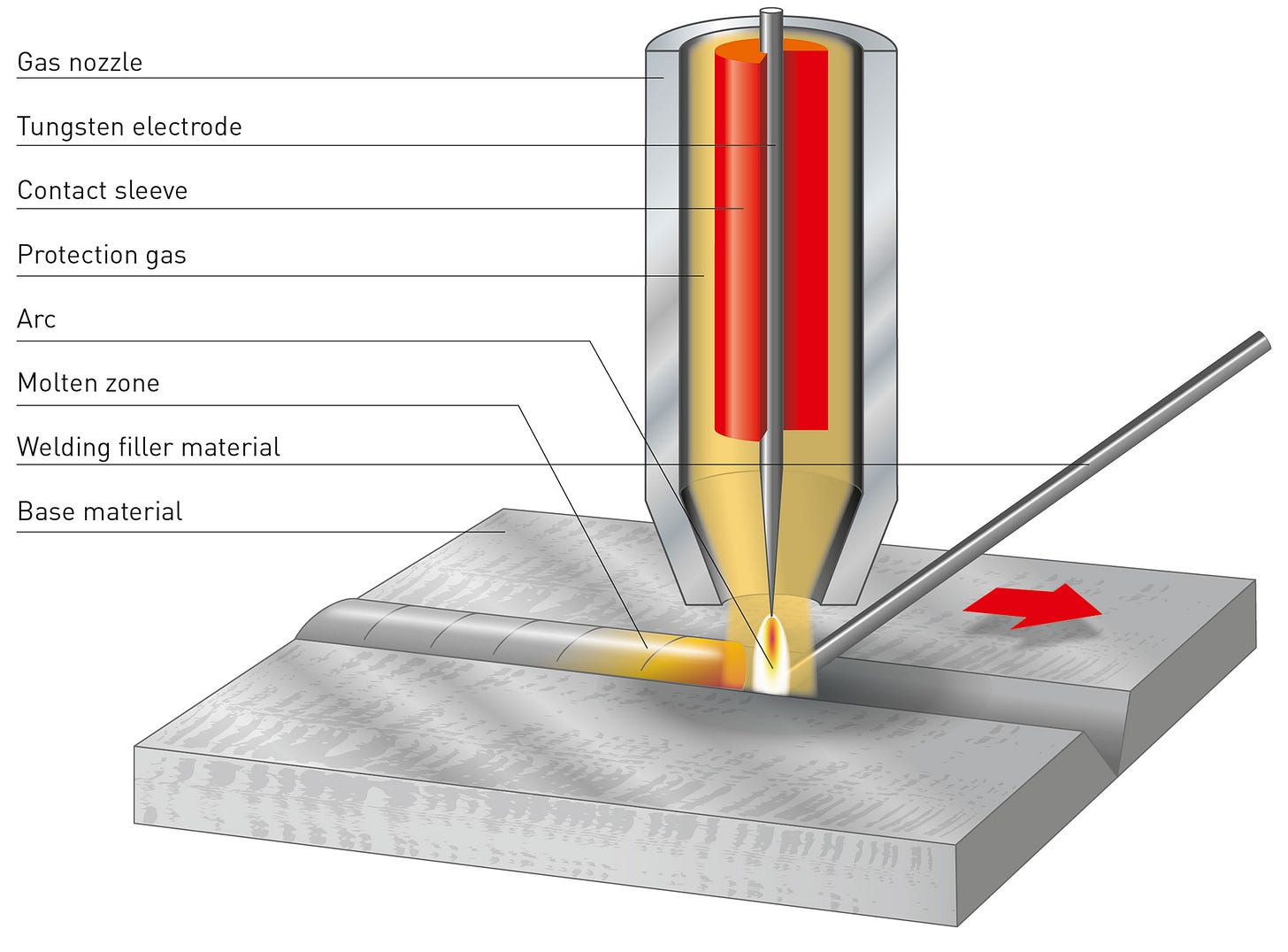

We’ll start with the realization that a reactor pressure vessel is often made of high grade 316L stainless steel and is about one foot thick. Now in order to join two massive foot-thick cylinders together you need to fill the gap with weld filler material, typically using a high-purity welding process such as TIG (Tungsten Inert Gas), where a thread of filler material is extruded into a weld zone melted by arc discharge from a tungsten electrode, with both electrode and weld pool shielded by a constant stream of argon gas to keep oxygen away and stop troublesome oxide layers from forming. TIG welding is slow, laying a depth of only a few millimetres of filler at a time, and at a speed of a few millimetres per second. Uniting metal with the touch of lightning. Slow and steady she goes…

It gets worse. Because the welding head is much, much wider than the filler wire it extrudes, it means that to fill a gap between two thick plates you need to machine a chamfer between them which expands from the inside to the outside, so you can fit the welding head in there. This means that not only do you have to slowly and tediously deposit weld material, layer-by-layer in a process that garden molluscs could outpace, but the number of layers and weld passes you need go up & up & up as the chamfer widens. By the time you get to joining something a foot thick, the chamfer geometry and sheer quantity of weld filler you need becomes ridiculous. Add in the requirement to use heating blankets to pre-heat the metal, perform frequent inspections of the weld beads and non-destructive testing of the join, and suddenly you find that you’ve spent a year just welding.

Solution one: Hot wire TIG.

Pre-heat the filler wire before it encounters the weld zone and you can speed up welding by up to 20%, which adds up. But we can go better…

Solution two: Narrow gap TIG.

I encountered this in my time in naval nuclear, many years ago, working on next-generation Royal Navy reactor core architecture. Shrink and slim the welding head and you can shrink the chamfer, rendering it slender and spry, a neat fissure rather than a gaping canyon. Do this and the number of weld passes you need plummets, and the time required to do the welding plummets with it. Less time and less welding means more capacity from less equipment, which is handy if you expect to be making a few of these reasonably quickly, as a nuclear submarine program requires that you do. But if we dip our toes in the water of the future, we can go one better again…

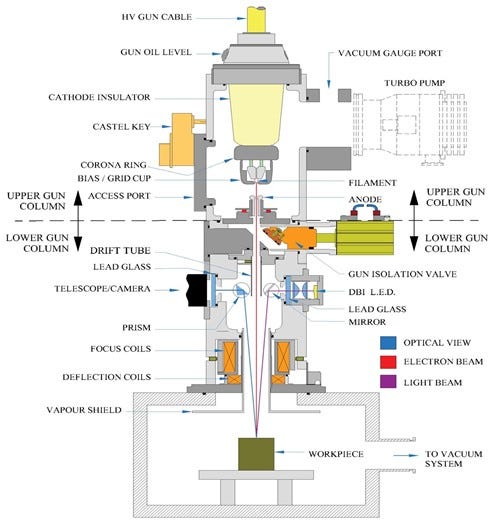

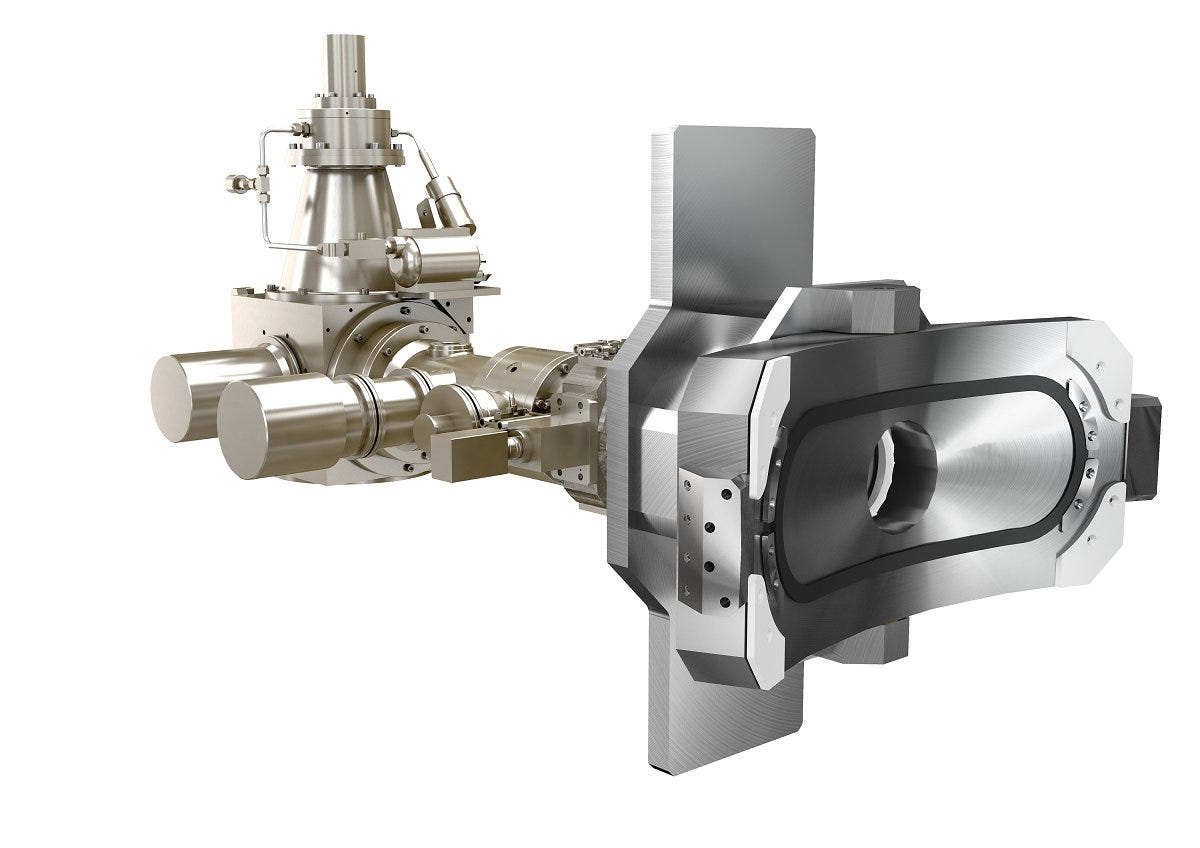

Solution three: Electron-beam welding.

Let’s throw away our tepid, incremental attitudes and do something revolutionary!

An electron beam welder is a special piece of applied magic. It sheds free electrons from a sharp electrode carrying high voltage, like an opening hairpin shedding Formula 1 cars. It then accelerates these electrons to between 30% and 70% of the speed of light, focuses them with coils and slams them into the workpiece in a beam of pure power, melting just about anything in its way. An electron beam welder is an autogenous weld technique, meaning that it does not use filler wire and simply welds two machined faces together in one blast. Unlike puny TIG with its lightning-caressed weld pool of a few millimetres depth, electron beams have serious penetration: Up to 200mm of depth can be welded in a single pass with tremendous speed, minimal material shrinkage and better retained strength than traditional welding. Brilliant! What’s the catch?

The catch is, unfortunately, that it requires a high vacuum to work. This is good in one way; an EB weld vacuum is ten times purer than a TIG weld’s argon shield gas and minimizes oxidation or hydrogen embrittlement, but the downside is that you have to supply this vacuum, and vacuum chambers capable of housing nuclear fabrications are spectacularly rare.

Unless you cheat.

Keep reading with a 7-day free trial

Subscribe to Incautious Optimism to keep reading this post and get 7 days of free access to the full post archives.