Forbidden technologies.

There are missing rungs on our technology ladder. Most of these are inconsequential, but some are not, and one of the biggest is the scarcity of really new nuclear reactor designs under development.

Until recently.

Most of the really pioneering work on novel reactors seems to have taken place decades ago, before a small handful of capable platforms grew to maturity and forced out all competition. Almost all of the current ‘Generation III’ reactors now under construction share this common design heritage, and almost all are either boiling water or pressurised water reactors; platforms well & truly proven over the decades. Well, why change a good thing?

There are reasons…

We're going to dive into one of the first of the ‘Generation IV’ concepts to become a reality in the near future: The lead cooled fast reactor. Will this latest attempt to steal fire from the gods succeed?

Or will it share Prometheus’ fate?

Let's find out!

1: The trouble with water.

One of the several big selling points of lead cooled reactors is heat, lot and lots of heat.

Most reactors running on the face of the planet, whether land-based or seaborne, pass either light or heavy water through the core as a primary heat exchange medium. This has its advantages: Water has a high specific heat capacity, is good at heat exchange, is stable and easy to pump and also functions as a moderator. This last bit is particularly useful, as water's average density goes down when you heat it sufficiently to boil it locally, which reduces moderation in turn, providing passive stabilisation to the reactor. This is all great. Water is great.

-Except that it boils at an inconveniently low temperature.

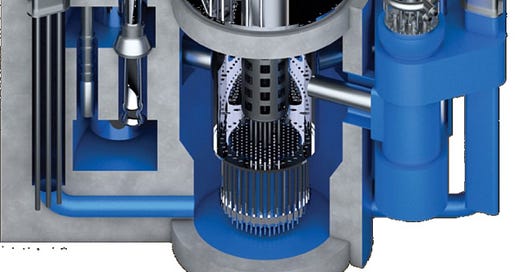

As we all know, at one standard atmosphere of pressure water boils at 100 degrees Celsius, and this doesn't sound low: It'd boil your skin off for a start, but for a rankine cycle heat engine, like a nuclear power plant, it's pretty pathetic.

In a rankine cycle heat engine, a working fluid (usually water) is pressurised and pumped through a heat exchanger which flashes it to steam. The steam then expands through a steam turbine, performing useful work, generating electricity etc, and is then condensed back to liquid form before being pumped and pressurised for a new circuit. It's the basis of almost all power station design.

There are, of course, unavoidable losses: It takes energy to pump and pressurize the fluid, and energy is also lost in phase changes between liquid and gas, that's difficult to recover if you need to keep damaging moisture content down in your turbine. Because these fixed losses exist, to improve the overall efficiency of the system it's best to add as much thermal energy as possible to the steam that's then recoverable (and usable) through the turbine, so that the ratio of usable energy to losses is as high as possible.

In short: Run it hot!

The temperatures achievable in the rankine cycle can be restricted by heat exchange limits, metallurgy, fluid decomposition… many things. However for nuclear reactors the main limit to rankine cycle steam temperatures and efficiency is the temperature achievable for primary heat exchange: A nuclear reactor, counter-intuitively, is quite cool. Certainly cooler than a furnace burning coal powder, for example.

Unlike in a coal furnace, a nuclear reactor core's fuel elements and their cladding need to stay intact while transferring thermal energy, whereas coal powder is just obliterated and burned. A consistent coolant flow ensures this, and the primary cycle coolant is a temperature limiter.

Water, as we've mentioned, boils at 100C at atmospheric pressure, so to make any real use of it in a nuclear plant we obviously need to pressurize it, and so raise the boiling point so it can run hotter while still remaining liquid in the core. For a boiling water reactor that means primary cycle water runs through the core at 75 atmospheres of pressure. For a pressurised water reactor, the most common type, where water must stay liquid throughout the primary cycle at up to 325 celsius, it must be pressurised to a brutal 150 atmospheres! The pressurizers actually dwarf the reactor core in a PWR!

So why not use something other than water in the primary cycle?

2: Element 82.

Let's talk about lead.

Lead is a stable element with a high atomic number, a low-ish melting point, a high boiling point and a very high density: The density is about 11 times higher that of either water or sodium (another liquid metal coolant).

The melting point of lead is 328 degrees Celsius and the boiling point is an almighty 1,749 which has some interesting implications. One implication is that at normal water reactor temperatures a lead coolant would freeze into a useless solid block, so it has to run hotter and stay hotter, which is a nuisance. However what lead gives back to us is an enormous thermal range, which means it can sit and soak up excess heat and reactivity for quite some time in a heat excursion scenario.

It can also do this at ambient pressures, which is much safer than pressurising the primary cycle to 150 atmospheres. The reactor core could literally run at the same pressure we walk around in everyday.

And as if that weren't enough, it's stability means that it doesn't activate and form short lived isotopes when bombarded by neutrons in a reactor core, which means that like water but unlike Sodium it doesn't need an extra secondary lead coolant loop outside the core for safety. This makes for a potentially simple reactor layout.

Great, so what are the drawbacks?

Well there's a big metallurgical one, which we'll get to later, but first let's start with the obvious: It's mad heavy. A density of 11 times higher than water, plus a surprisingly low specific heat capacity (30 times lower per kg than water) means that you need to carry around a serious amount of mass in the nuclear primary cycle, which complicates surrounding structures and earthquake resistance.

It's also not transparent, unlike water, which makes refuelling difficult, even before the realisation that you'll need to refuel while the lead coolant is still a liquid, and therefore incredibly hot. This is eased somewhat of you use a substance called lead-bismuth eutectic (LBE) instead of lead, which melts at a much friendlier 124 Celsius, but LBE is a lot more expensive than lead, so pick carefully.

We could go deeper still, -and we will!- but first let's step back a bit and cover the basics: What happens inside a reactor core, and what's all this talk about “primary cycle” and “secondary cycle” about?

3: The nuclear island.

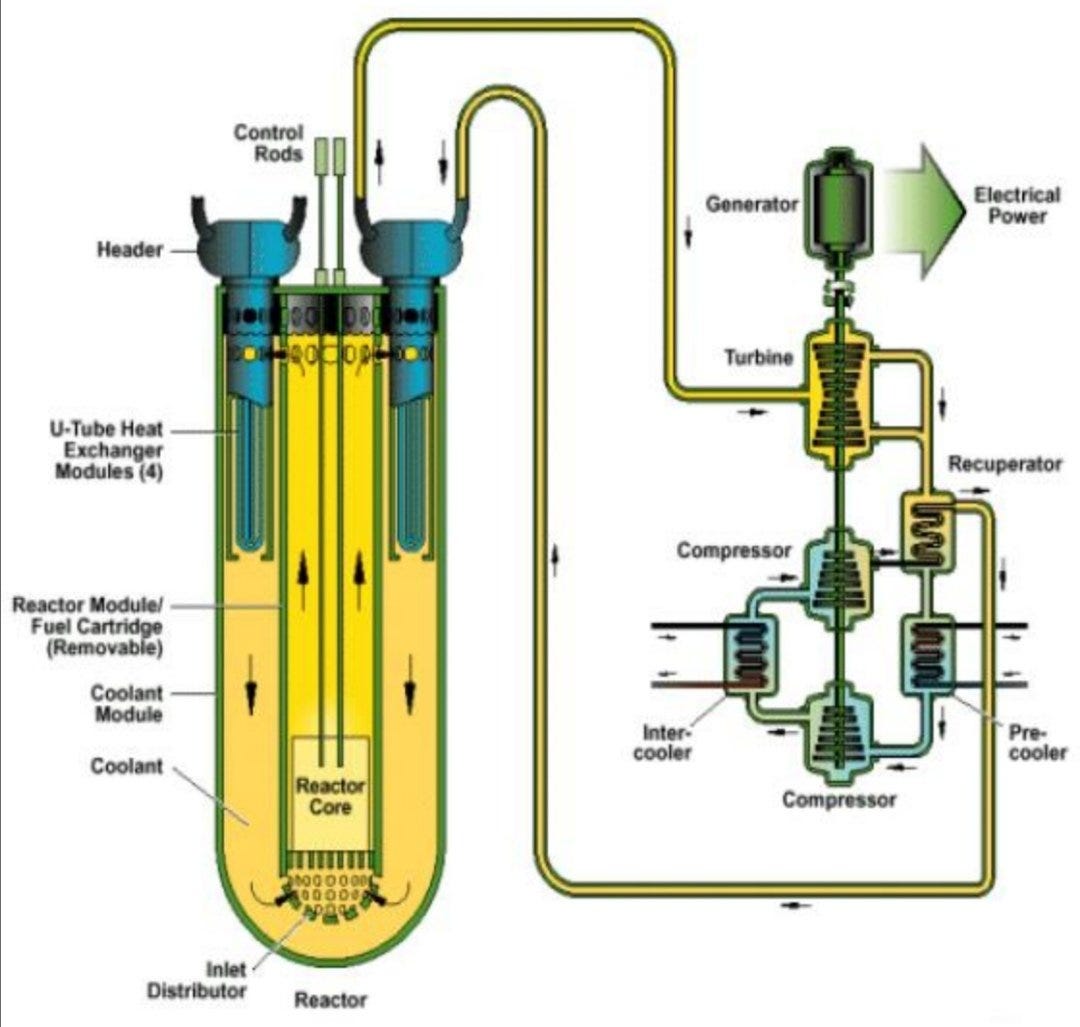

The primary cycle is the coolant cycle that runs through the reactor core, where Uranium and Plutonium undergo nuclear fission, releasing heat and a barrage of neutrons, a fast-moving subatomic particle. The secondary cycle, if there is one, is the cycle that turns pressurised liquid water into steam that expands and powers a turbine for power: That's the bit we talked about when we discussed rankine cycles earlier, and it needs to be pressurised in order to be able to expand and release its energy productively.

In boiling water reactors the primary and secondary circuits are one and the same, but these are a special case and in most reactors they are separate, linked through heat exchangers.

And in such cases, the primary cycle exists primarily to supply heat. Lead is good at this.

But there are reasons to segregate primary & secondary cycles: One is to prevent neutron-activated radioactive isotopes from leaving the shielded nuclear island. This isn't an issue with stable lead. The other is if the primary cycle coolant would be no good running vapour through a turbine: Lead would be useless for this, so the two coolant circuits shall remain separate.

4: History, mystery and Red lead submarines.

Russia tried it out in anger first: In the 70s & 80s the November and Alpha class nuclear submarines served the Soviet Union, powered by lead-bismuth cooled reactors. The intent of this was, simply, that the high thermal conductivity of lead, combined with the high operating temperatures in the primary cycle, allowed for use of a smaller, higher power density design. Combined with the fact that the primary cycle could run at ambient pressure rather than 100+ atmospheres, this also significantly cut down on wall thicknesses and resultant weight of the primary cycle system.

Compact, lightweight, allowing for high enrichment and therefore long periods between refuelling… you can see why that was appealing in a nuclear submarine.

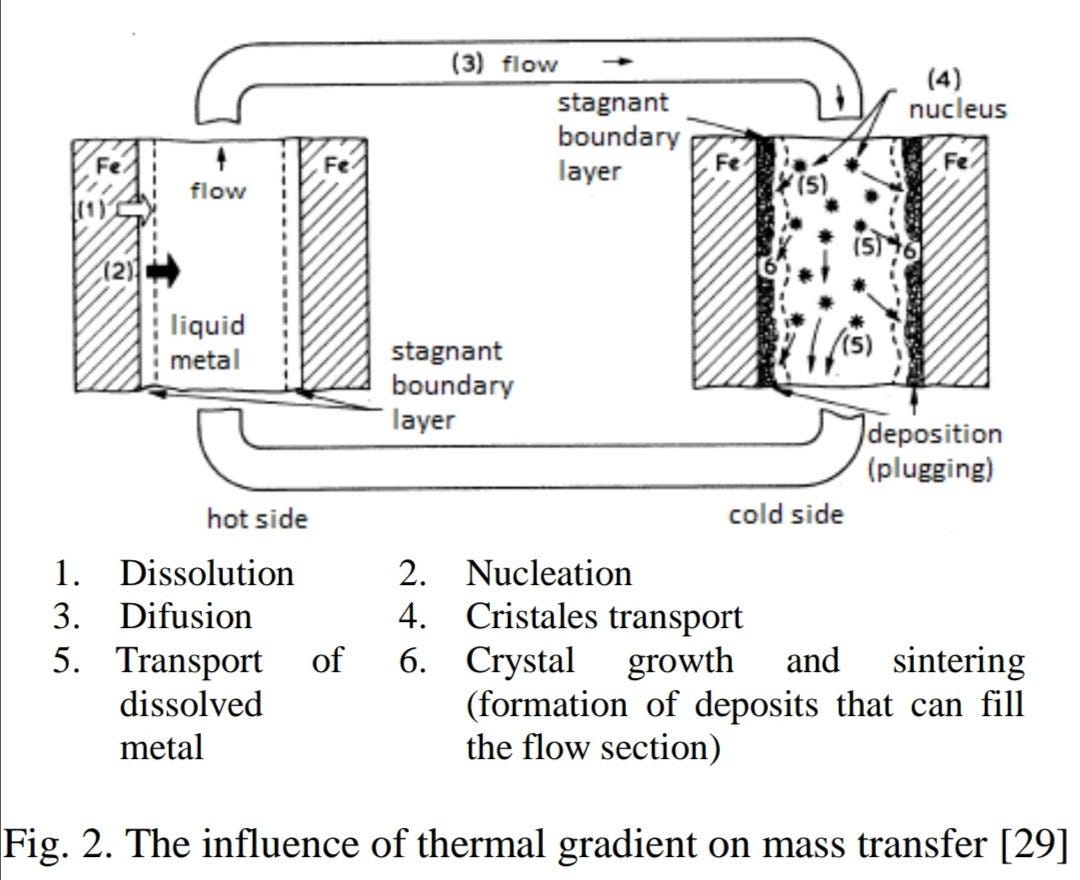

The Russians also learned from hard experience the downside of lead & LBE cooled reactors: Molten lead creates a brutal corrosion environment on steels, operating partly from conventional oxidation, but also dissolution of the metal in the flowing lead and mechanical erosion from the high density coolant. This gets worse with increasing temperature.

Conventional corrosion control mechanisms include control of oxygen levels inside the primary cycle: Sufficient for growth of protective oxide films over the affected steels but no more. One nuclear accident on a Russian LBE submarine, resulting in partial meltdown, was traced to a core blockage from LBE oxides occuring during maintenance. Control procedures, oxygen monitoring & oxide purification were all hardened subsequently.

Up to 550 Celsius, austenitic steels such as the common 316L are plausible for lead cooled reactors. Above this temperature, advanced martensitic steels and ceramics will be required, and research is simply too immature right now for this.

As if this isn't enough to deal with, using LBE instead of ordinary lead means that radioactive Polonium 210 is produced in the primary circuit, and must be removed. Dealing with this is a design choice, and the Russians opted to take the LBE path and do exactly that.

The Soviets eventually retreated from LBE reactors in their submarine fleet and opted for more conventional pressurised water systems instead. This may have been partly due to the risk of LBE or lead coolant freezing solid if it gets too cool, as happened to one submarine while it was under the Arctic ice cap. A land-based power station could potentially recover from this using outside energy sources, but a submarine in operation? Not so much.

But that was then, and this is now. As we will see, Russia is about to jump back into lead reactors in a big way.

5: Passive safety.

Now that you've been appropriately scared by the last section, it's time for some good news, because a Lead cooled reactor has some interesting features that add to passive safety, and therefore simplified builds.

Firstly we'll clear the obvious out of the way: With a boiling point above 1,700 Celsius it's incredibly unlikely that voids in the coolant would lead to runaway thermal events in the core, as the cladding would melt before the lead boiled (also a Very Bad Thing, but let's get back to that in a bit).

Secondly there's the ability to passively cool, without pumping, thereby making a suitable lead cooled design completely resistant to a Fukushima or Three Mile Island style meltdown event. This is due to lead’s low core head losses and very high density, meaning that it's very possible to design a lead cooled core that will convectively cool itself through heat alone if the coolant pumps were to fail.

That, of course, only applies to the primary circuit, so if the secondary circuit had a complete circulation failure you'd still have a thermal buildup to deal with, but with lead’s huge thermal range, and the potential for a large reservoir in the design, you could stretch this out sufficiently to give plenty of time to respond. In addition to this, many lead cooled reactor designs currently on the books have additional passive heat removal systems for this eventuality, making a Fukushima event effectively impossible.

This is the fundamental design premise of the GenIV reactors: To ensure passive safety. This can be done through passive convective primary coolant convection plus convective air or gravity fed water secondary backups. It can also be done by fuel cladding design: The metal alloy cladding materials typically used to contain the fuel (Zirconium alloys in pressurised water reactors, steels in lead cooled reactors) have lower melting points than the Uranium oxide fuels they contain. In a catastrophic loss of coolant scenario, that leaves the possibility that residual decay heat, uncooled, could cause local centreline melting in fuel pellets, which could cause cracking and exposure of molten fuel to the cladding, which would fail and release dangerous isotopes into the primary circuit. Very, very unlikely, but nuclear engineering is all about designing for such eventualities.

Happily, there is currently research underway on ceramic fuel cladding materials, which would eliminate this risk entirely.

So whether by passive cooling mechanisms or, eventually, novel fuel cladding options, GenIV reactor architectures can safely eliminate a vast array of the active controls and safety measures in place on current generation nuclear reactors. This in turn drives simplicity, an easier regulatory approvals pathway and drastically reduced costs.

Simpler, quicker, cheaper. What's not to like?

Speaking of which…

6: The Small, Modular niche.

The Small, Modular Reactor.

Rarely has such a niche technical phrase carried so much forlorn hope. The SMR represents the ardent wish of a certain type of tech-bro for magic technology with all the upsides of nuclear power and none of the downsides.

By ‘upsides’ we mean clean, abundant, on-demand climate saving power. By ‘downsides’ we mean over-regulated, sluggish expense, trapped by the glutinous constraints of one-off builds and planning consent.

So basically the cheap ubiquity of modern solar power but compact, deployable anywhere and with the ability to switch it on anytime, even at night.

The SMR is one of those weird things, like nostalgic 50s Americana or sci-fi from that period: A space-Chevrolet dream of a rocket powered future that never quite matches up with reality.

But perhaps it could, if we gave it a really good go.

The logic is simple: All mass manufactured consumer products have dropped massively in price, even as they've gained in quality, subject to the learner effects of mass production, leveraged capital investment and gradually sharpening expertise that only occurs when you have to stamp out the same thing again & again and drive down the cost of doing so, even while you add new features.

And in areas where competitive mass manufacture has not been able to touch, like education, most health care and, indeed, nuclear new builds, the opposite has happened: Expense blooms and each application of expertise becomes a human-glue bespoke deployment.

OK, there's not much we can do about a trip to the doctor, but surely we can apply mass production learner effects to nuclear builds?

The SMR concept is that: A complete plug-&-play plant architecture compact and self contained enough to be produced in a central facility and shipped to assembly zones, with a maximum of engineering content centrally located and a minimum amount on the build site.

Maybe it'll work, maybe it won't. It's never actually been attempted on the scale required to make it a success.

But if it does, lead cooled reactors are a plausible niche. Their compact, passively-safe high power density design meshes well with the SMR industrial concept.

Even if it does, is that relevant to today's world of variable renewable energy and extracting power from the breeze? Are nuclear grands projets a thing of the past?

Well, given France’s nuclear electricity exports to it's European neighbours, probably not.

7: Tilting at windmills: Thermal batteries.

Nuclear power is seen as old hat and unfashionable for a variety of reasons, and only part of this is the general public's understandable superstition and distrust about radioactivity.

After all, while nuclear power is statistically very safe, the same is true of swimming in the sea on holiday, but I still look at inky waters beneath me and get a sudden panic that there might be beasties down there!

No, the other reason that nuclear is out of fashion is a strange inversion of it's virtues: In a world where cheap but fundamentally random solar and wind energy sets the price of electricity, how do you price a monolithic fifty year asset like a nuclear power station? The two generation methods seem to be at loggerheads.

But they needn't be.

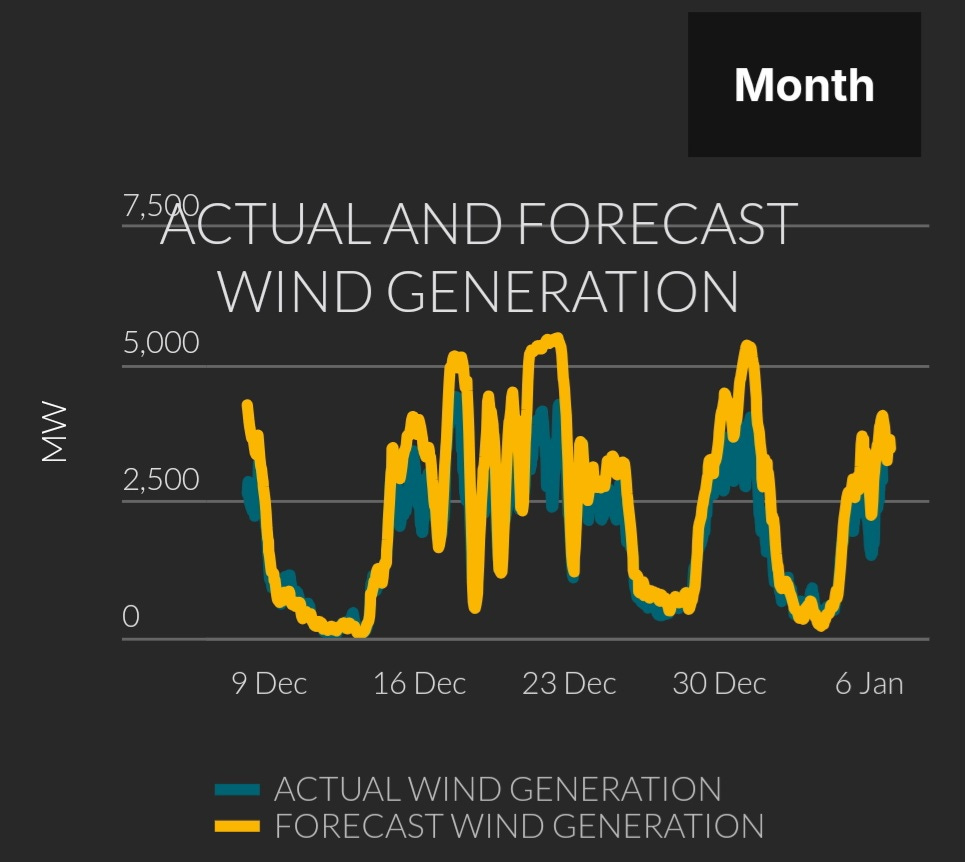

With lead’s high core exit temperature, there is the potential to couple it with a thermal molten salt cycle, to store thermal energy when energy prices are low (i.e when renewable power is abundant) and release it when the grid needs extra. This is not something that's been attempted with lead cooled designs before, but any sufficiently high temperature primary cycle could theoretically work with thermal molten salt storage systems, and they are already widespread in concentrated solar power plants worldwide. See the Eirgrid smart dashboard image below for an example of what this variable generation looks like for Ireland (admittedly a non-nuclear country).

Add something like integrated thermal storage and nuclear power becomes a bedfellow to renewable energy, not a rival.

8: Industrial heat.

The vast majority of energy output from a nuclear reactor is waste heat, which is vented away into rivers, seawater or the air itself. Making use of it would be useful.

In some countries, waste thermal energy from power generation is used for residential purposes, but there are higher intensity industrial uses too: See, for example, the article I published recently on desalination technologies.

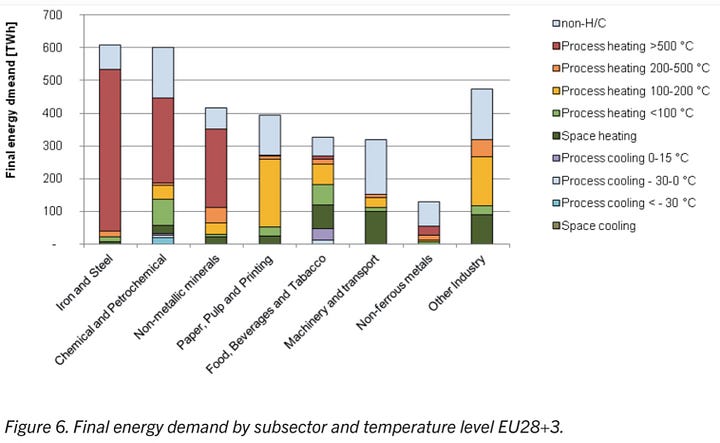

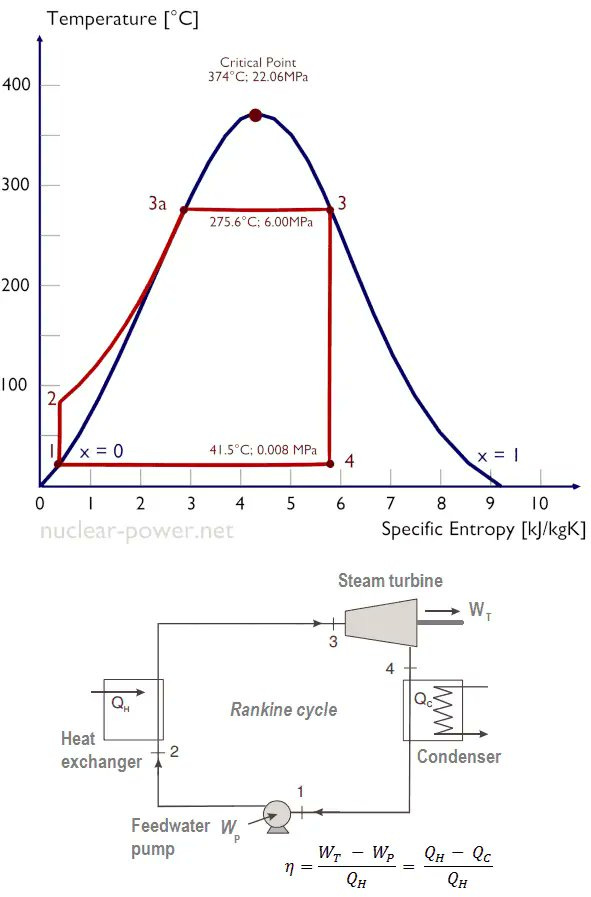

And from refining through chemical processing to industrial process steam generation, there are scores of industrial thermal applications that are hard to decarbonize through conventional means, see the attached images for Europe alone.

Perhaps it's a pipe dream, and popular consent would never be granted, but a small deployable 550 celsius nuclear primary cycle, with the potential to go much higher if metallurgical science makes a few key advancements, could unlock more than a few doors in this area.

It's worth exploring.

But there's something bigger to consider first, and to understand it we're going to go over some basic nuclear physics…

9: Speedy neutrons.

All of this is useful, and from the detail above we've painted a fine picture of lead’s utility, with songbirds and rainbows to boot.

But follow this particular rainbow to it's end and you may find a pot of gold.

For lead has one other special property, which is that its atomic mass makes it a great neutron reflector.

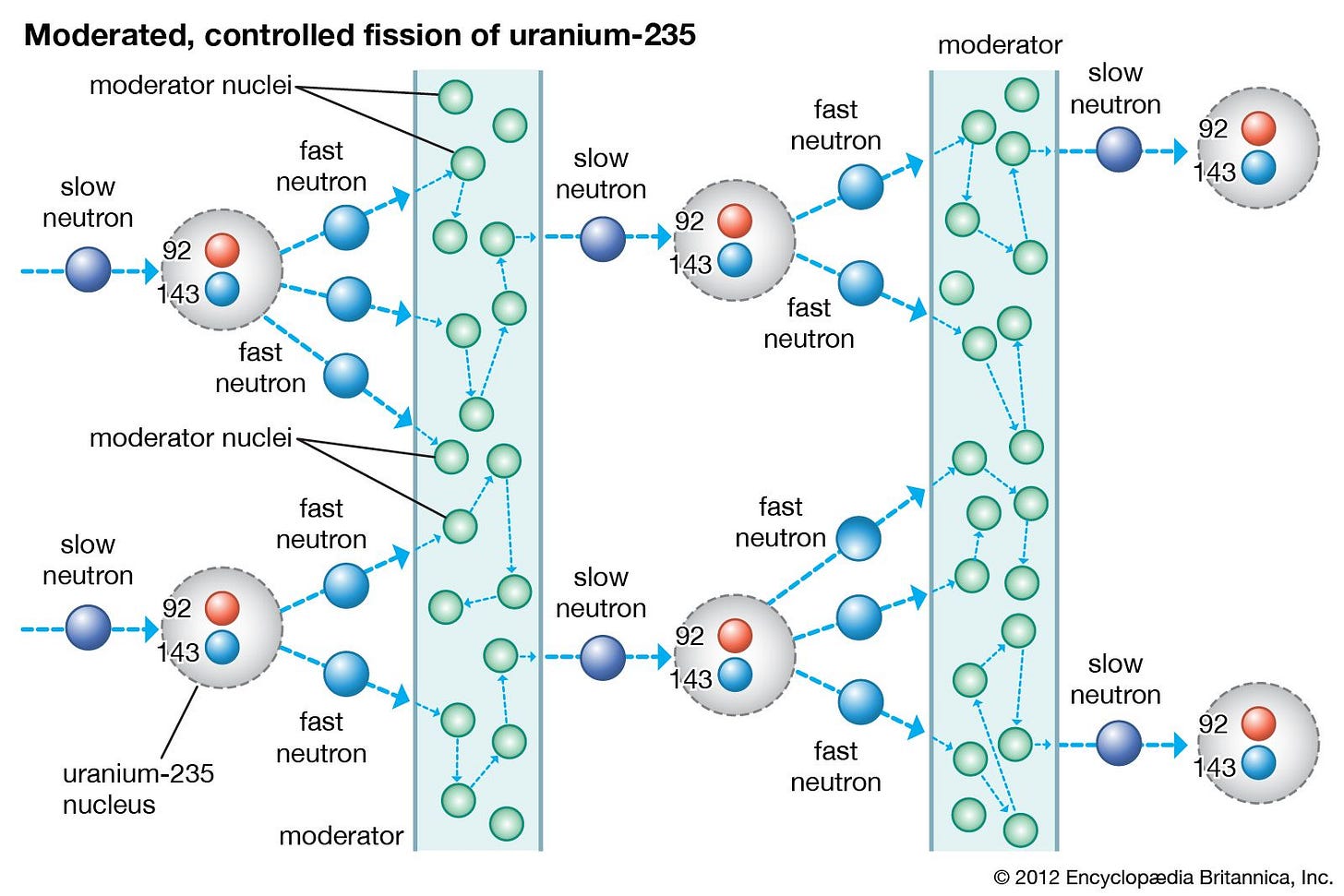

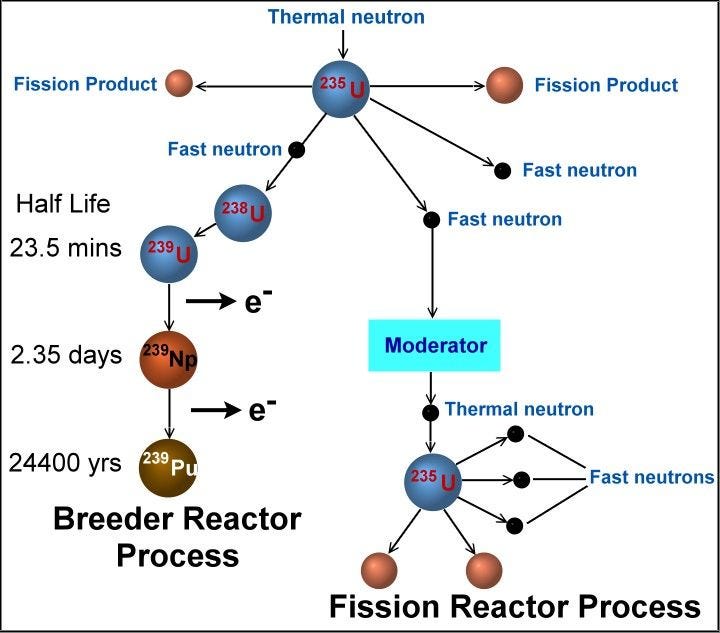

Fission, as we may know, requires neutrons hitting and destabilising a Uranium 235 nucleus, causing it to fission into other isotopes, releasing a bundle of energy and several other neutrons in the process. These may go on to hit more U235 nuclei, etc, and so we have a chain reaction.

OK, grand, but a few subtleties are being missed. One is that the chances of an individual neutron causing a fission event when it hits a U235 nucleus are vastly increased if it is first slowed down.

How do you slow down a neutron?

In a nuclear reactor, you use a moderator: A substance with a low atomic weight (like hydrogen or carbon, present in water and graphite respectively) that absorbs some of the neutron’s energy.

Think of it like pool or snooker: If the white ball hits another ball, some of its momentum transfers to the other ball and it slows down. If it hits the felt covered side of the table instead, it bounces back just as fast.

A lead atom is the side of the pool table.

This makes it ideal for use in a fast breeder reactor, which is the real “generation IV” aspect of this technology: Keep the neutrons moving fast and you can start transmuting far more common Uranium 238 into usable fuel, or reprocess high level nuclear waste by ‘burning’ it up. These abilities, unique to fast reactors, mean it can make better use of nuclear fuel, go longer between refuelling and leave less waste when it gets there.

Conventionally, fast breeders are tricky to run and about 20% more expensive at a minimum than normal thermal reactors, but the relatively simple, compact, passively-safe architectures of lead cooled reactors could up-end this.

Fast reactors are also Plutonium breeders, so nuclear proliferation is a primary concern: It's important to ensure that the stuff is burned off as fast as it's created in such designs.

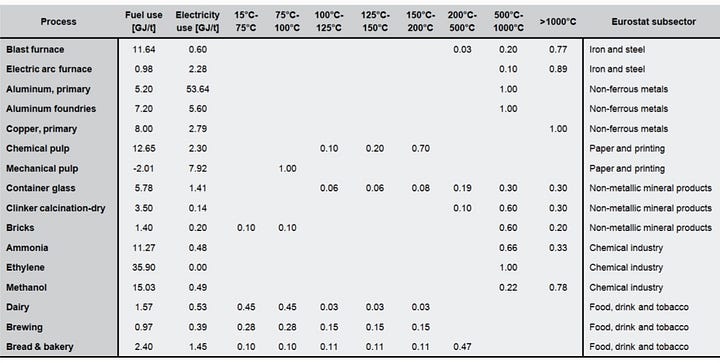

But lead fast reactor, or LFR designs are being put forward for government approvals in a wide range of countries: The Westinghouse LFR small modular reactor, the Newcleo LFR-AS 200 small modular reactor, now being put forward for justification in the UK & France …

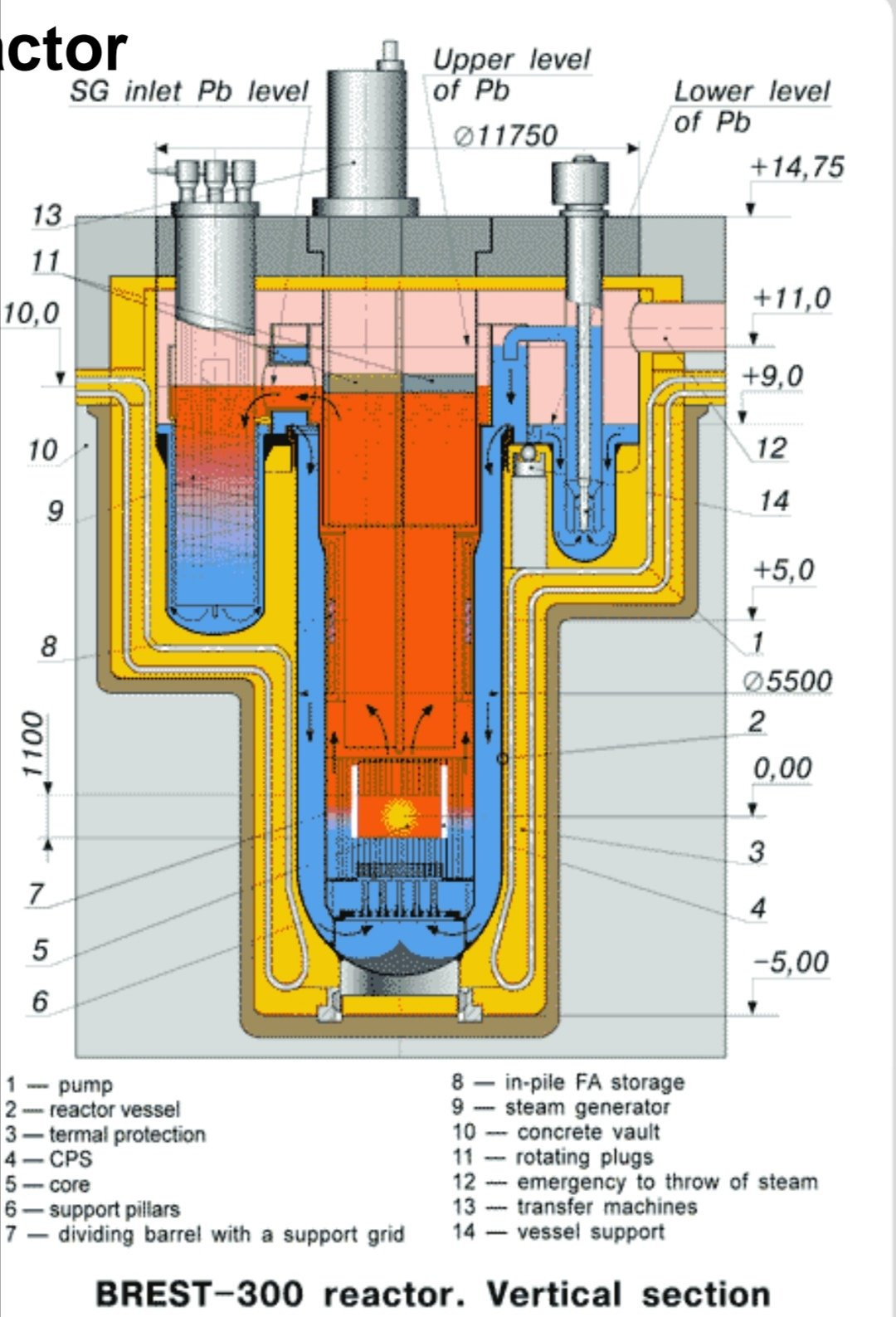

And the Brest 300 in Russia, the only LFR anywhere in the world that isn't just fully designed and approved, but is actually under construction.

It comes online in 2027.

The Future is arriving.

10: The Future Is Lead?

The Brest 300.

That it's Russian should surprise nobody: The Russians have been nuclear power pioneers for many decades, and even now have ownership of a significant amount of the full nuclear fuel & waste processing cycle, which is where a fast waste burner like the Brest 300 fits well.

Not quite an SMR but not oversized either, the Brest 300 is a small 300 megawatt template for something larger to follow: A 1.2 Gigawatt beast called the Brest 1200. It features a mid-sized lead (not LBE) primary circuit with four steam generators bedded into the core itself. Curiously, the steam generators have a very particular design limit to work within, as they exchange heat energy with a 540 celsius lead primary cycle.

That is, they cannot be allowed to freeze the lead.

And since the Brest 300 will run on pure lead, not Lead-bismuth eutectic, that means that the entry temperature of the liquid in the secondary cycle steam generators needs to be a whopping 337 celsius or above to avoid freezing the lead, and this is before it enters the heat exchanger to be flashed to steam by the energy of the primary cycle.

And how do you keep water a liquid at that kind of temperature? You pressurize it, so we're back to that problem again. In this case you need to pressurize the Brest 300 secondary flow even more than a pressurised water reactor primary cycle, because you need a monstrous 220 atmospheres to keep it a subcritical liquid at such monstrous temperatures. It then converts to supercritical steam after soaking up all the energy in that steam generator.

Supercritical fluids are strange things. Above 220 atmospheres and 374 celsius, water becomes supercritical, neither fully liquid or gas but an odd sort of hybrid which converts with increased temperature from being more liquid-like to more gas-like without a distinct phase change. Using it in a rankine cycle brings efficiency benefits, which is why modern coal plants tend to run supercritical. The fact that a nuclear core can run hot enough for supercritical steam cycles to even be an option is extremely impressive.

But it still means that part of your highly controlled and expensively perfectionist nuclear island still needs to be equipped for high pressures, which is not ideal.

Maybe some complexity is unavoidable.

Run pure lead? You'll need a supercritical secondary cycle. Run LBE? You've a much bigger temperature range to play with, but now you need to deal with Polonium and other nasties. In both cases you need to conquer the corrosion challenge to run any hotter.

Or you could run sodium instead of lead and keep the entire nuclear island at low temperature, leaving the steam generators in a less heavily regulated, cheaper build environment? But then you need two doubled-up sodium loops due to the challenges of that particular coolant, which may cancel out the cost benefit.

Maybe it's just compromise, all the way down?

Engineering often is. Lead fast reactors have very particular shortcomings, corrosion and material selection being foremost among them, but these are solvable and the real lesson of Brest 300 is that a physical, built reactor is going to be there to prove it. If it works then that opens a door to all kinds of possibilities, as the world learns the Russian lesson and follows suit. In a good way this time.

Or we could just keep on building light water reactors, which are known factors that could probably be done faster. Presence beats perfectionism, most of the time.

That said, you have to try something new and promising once in a while, else you never advance. Russia is doing that with the Brest 300, so we should all keep an eye on it, and look for inspiration.

Someone has to be first.

Fire from the gods…

Credit for images and data goes to: A Comparison of Advanced Nuclear Technologies, Andrew C. Kadak/ Overview of Generation IV (GenIV) Reactor Designs, IRSN/ Lead Cooled Fast Reactor Systems and The Fuel & Materials Challenges, T.R Allen/ Lead Cooled Fast Reactor (LFR) Overview and Perspectives, L. Cinotti/ Corrosion of Some Candidate Structural Materials for Lead fast reactors, Dumitra Lucan/ and the Generation IV International Forum.

I don't know how likely it is but there appears to be an emissions or cost risk with greatly expanded conventional nuclear. Ore grades are expected to decline and the energy to mill in particular rises exponentially. Mines using current energy mixes would result in nuclear at 60gCO2/kWh in 2050 rather than 12g as it is now. Still low but notable

Milling is an electric powered activity so it may not be difficult to deliver low carbon energy to the mines to offset this, but the remoteness of the mines could make that pricey. With LFRs able to use the whole ore this effect would entirely dissappear for the reasonable future

You could use a solar salt secondary circuit, which you would need anyway for thermal storage.

That would put the steam generators outside the containment *and* potentially outside the nuclear regulatory scope.

Solar salt also has a ~550C practical limit, so it's a good pairing.