One airliner looks very much like another these days, but what if that wasn’t the case?

I’ve written recently about the long, long list of technologies primed to take the humble jet engine and make this complex beastie even more complex, more mysterious and more efficient. But this is a hidden detail in the heart of an aeroplane, and the average punter will never see its manifold wonders.

What about the plane itself?

If you’re an insider to the aerospace industry it's easy to forget that normal, everyday people don’t actually get all excited about the launch of a new Airbus or Boeing, and don’t reflexively look at every long distance airline booking to find out what type of aircraft they’ll be travelling in. Most people, in fact, don’t care.

And why should they? Squint, and a photo of an Airbus A330 and a Boeing 787 look pretty much the same, even though 27 years separate the first flight of each family of aircraft. If cars were treated the same way then Jeremy Clarkson would never have made millions, Top Gear would have been in the Sunday TV schedules next to Countryfile and no teenage boy would be seen dead with a Lamborghini poster in his bedroom.

Has any teenage boy anywhere hung up a poster of an Airbus A350? Exactly.

…It’s worth noting at this point that I did, as a youngun, have a poster of a ski-equipped Arctic LC-130 Hercules, but I’m not a normal person. Moving on.

A lot of the reason for this studied lack of interest is that aerodynamic innovation on civilian airframes isn’t moving apace with propulsion or materials innovation. The cylinder-with-cantilever-swept-wings approach is standardised, works well with mass production and is lower risk than trying for anything weird, even if it’s not aerodynamically optimal, so why change it?

Well for one, we may have to. Fuel efficiency demands, and carbon budgets, are tightening the screws ever more and the 1% per annum efficiency saving that propulsion can give you won’t cut the mustard on it’s own, and nor can material improvements when most of the bulk of a modern airliner is already lightweight carbon fibre composite.

What can we do?

Enter the latest NASA X-plane project: The Boeing X-66A.

Let’s take a step into the future…

1: Into the vortex: Induced drag

A lot of the secret sauce of aerodynamics comes down to reducing drag in clever ways, while retaining the aircraft's ability to do useful things. The lower the drag, all things being equal, the less power you need to push the aircraft through the air. The less power, the less fuel is needed. The less fuel, the lower the weight, which feeds right back into drag again.

Ideally we want an airliner to cruise effortlessly like an albatross, not frenetically like a fat pigeon.

The shape of those two birds give a hint as to what is useful: The pigeon, adapted for sudden bursts of speed and manoeuvrability, has short stubby wings and a compact body. The albatross, undisputed king of the long distance ocean sabbatical, is sleek and streamlined with a skinny wing spread over a very, very wide wingspan.

The length of the wing, front-to-back, is called the chord. The width of the wing, horizontally and perpendicular to the airflow, is called the span. Divide the span by the mean chord and you get something called the aspect ratio: The albatross has a very high aspect ratio wing, the pigeon doesn’t.

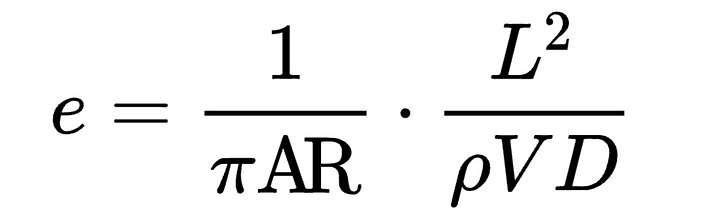

This has to do with something called induced drag, and it’s important because induced drag makes up 40% of all the aerodynamic losses on a cruising airliner, so minimizing it is a Very Good Thing.

Now look once again at the X66 and consider: Albatross or pigeon?

There are a few different types of drag that act on an aircraft: The main ones are parasite drag, induced drag and wave drag.

Parasite drag is the effect of momentum being transmitted from the aircraft to the surrounding air through skin friction, wake effects, flow separation and interference effects at structural joins. It is not linked to lift production.

Wave drag occurs due to compressibility effects when flying near to, or above, the local speed of sound. It occurs when airflow is moving too fast for it to ‘get out of the way’ of the structure, and shock waves develop as a result which decelerate the air, change it’s direction and heat it up. Obviously, this is a lossy process, but airliners usually skirt the lower limits of speeds that can lead to this.

Induced drag is a whole different animal, because it occurs as a direct result of the aircraft generating lift, and is the type of drag that is directly affected by the aspect ratio and shape of a wing.

Puzzled? Not for much longer. Let’s explain.

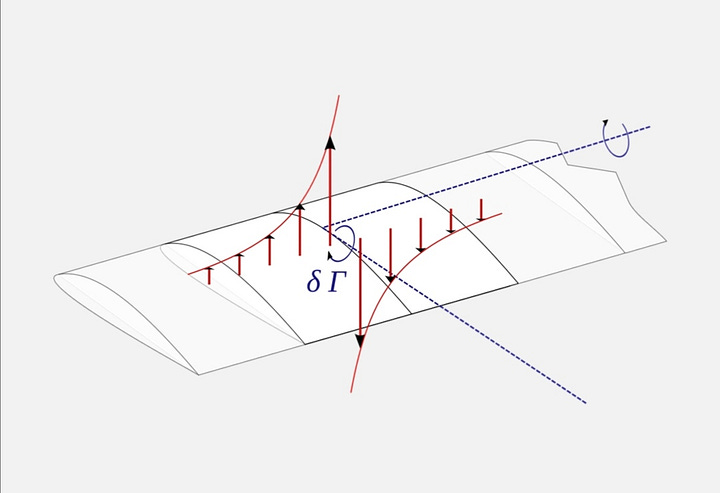

A wing generates lift. We won’t go into how, because that’s a whole topic on its own, but the result is a high pressure region under the wing, and a low pressure region above it, centred around the wing quarter-chord, which is where the effect is most pronounced. The difference in pressure (and some momentum transference to the air) generates net lift over the wing.

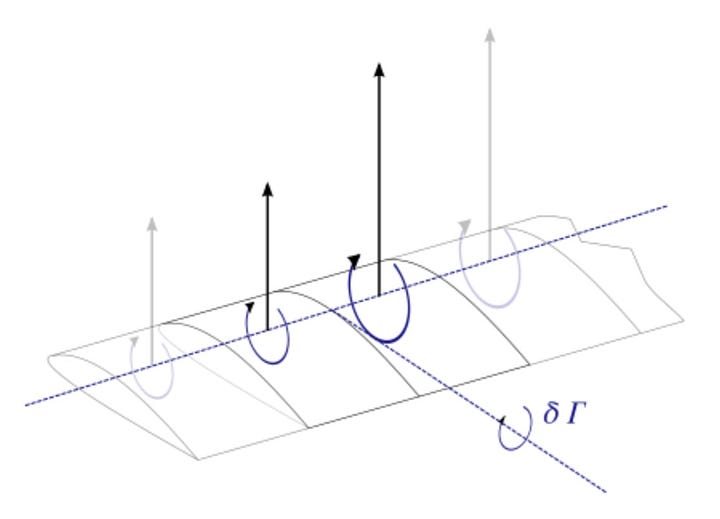

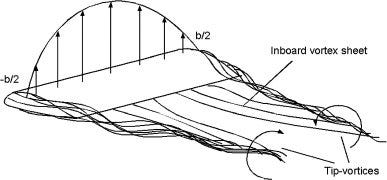

OK, great. But the problem is that nature doesn’t like high & low pressure zones sitting right next to each other, and will try to correct for this. The net effect of this is that air from below will ‘curl over’ the wing and generate vorticity across its span, which will curl up and concentrate at the tips into two opposing vortices, which trail behind the aircraft.

Is it a sunny day where you are? Look up and try to find the contrails of a plane!

What you will see is that the contrails are produced by the engines as water vapour from the burnt fuel condenses in the cold stratospheric air. It doesn’t stay in the engine wake for long however: Look closely and you will see the contrails get sucked up into a huge vortex structure, with two trailing vortices stretched out across the sky. Keep watching for long enough and you’ll see them collide in places, combine and separate into stretched-out doughnut shapes way, way up, written on the sky by a mad calligrapher.

Now back to the plane! Visualize these vortices and the flow between them. As they curl around, the air between them is pushed down, and because the plane isn’t supersonic this downward flow affects the air in front of the plane as well, pulling it into a downward trajectory in front of the wing.

And because the lift produced by a wing acts perpendicular to the direction of the airflow that means, if you sketch it out in a side view, that a component of this lift is now acting backwards!

There’s a name for a force acting backwards, against an aircraft’s direction of travel: Drag.

This is induced drag.

So how do we stop it, and what has this got to do with our friend the albatross, and the X-66? Stick with me and I shall explain.

2: Lifting Lines.

We can start with an aerodynamic approximation called lifting line theory.

If you kick a football with some spin on it, the football will curve in the air in the opposite direction to that spin. This is caused by variations in drag & lift across both sides of the spun football imposing a moment of force, and you can approximate this by modelling the football as a bound vortex in the direction of the spin.

Now imagine an aircraft wing, evenly divided, as a whole bunch of these bound vortices next to each other, generating lift.

You can even input a simple boundary condition: The lift is zero at the wingtips.

Where there is a difference between circulation strengths between adjacent sections in this bound vortex (resulting from, say, differences in wing segment area or a boundary), simple geometry tells us that this results in a perpendicular vortex stream being generated to account for this velocity difference. In lifting line theory this is assumed to be shed downstream but remain bound in the spanwise direction to the wing segment it originated from: That last bit doesn't map onto reality, but remember this is an approximation!

Now remember our description of induced drag: Induced drag results from a downwash in airflow into an aerofoil, and that’s exactly what these shed vortices will create between the wingtips. Lifting line theory not only gives a rough method to work this out, but also allows us to integrate the effect across all the wing segments to see the effects of wing shape on lift distribution and the lift: drag ratio.

Basically: The efficiency factor improves with increased aspect ratio, and the lift: drag ratio rises with increased aspect ratio.

So long story short: Albatross.

Now, enter the X-66…

3: Strut-Braced Wings: The return of something old.

There may be something familiar about the images of the X-66 above; familiar and a little archaic, despite its futuristic planform and areas of sexy forward sweep.

You’d be right. The strut-braced wing is not a new concept, but a very old one, driven originally by the limitations of aerospace materials. Back in the early days of wood, cable & fabric bound aircraft, a frequently-occurring design was a wide, high mount wing with a set of structural braces rising from the lower fuselage to meet it. This was lossy and ultimately relegated to history by the modern cantilever wing box and improvements in material science. The conventional strut was also poorly optimised for the swept-back wings that transonic aircraft require.

But if the strut wasn’t a purely structural component, if it added lift and was backed by geometrically-flexible carbon composite construction and advanced CFD-aided iterative design, you can get around the negative aspects and yield the positive benefits: The ability to support a wide, high aspect ratio wing that conventional cantilever construction simply couldn’t support.

And if you have the rigidity (provided by carbon composites and computer-aided design) to make that lifting strut a forward-swept component, then it becomes useful with all kinds of transonic airliner designs.

But back-up a minute: Why would we want a strut in the first place?

A pure cantilever wing is simple and aerodynamically clean, which is why we see it on high performance sailplanes, even with extreme aspect ratios, but a sailplane isn’t an airliner in much the same way that an angel isn’t a mule: One has to carry heavy loads without complaint. An airliner’s wings are heavily stressed and must carry fuselage loading and heavy underslung engines with a lift distribution that drives a long moment arm from tip to fuselage. This requires stiffness, which in turn demands weight.

Any modern airliner has wings which need to be capable of withstanding 2.5g of acceleration, which would not seem out of place on a roller-coaster (though few passengers ever experience this!) This means that if you expand the aspect ratio to extremes, the stiffness and rigidity demanded by the wing box eventually erodes the aerodynamic benefit by piling on extra weight to your airframe.

By adding a lifting body strut of opposite sweep, the inner one third of the wing structure is significantly stiffened, without extra bulk, meaning that an ultra high aspect ratio wing becomes possible. Make the main wing a high mount, the lifting strut a low mount and mount engines in between and you have a usable high efficiency platform.

Eureka!

Except… a problem remains.

4: Squeezing through the gate.

A typical narrowbody airliner like the Boeing 737 or Airbus A321 has a wingspan in the region of 36m, just right for fitting snugly into airport gates with a little room to spare.

The X-66 however, however graceful it may be in the air, will be just as ungainly as the albatross on land and simply will not fit those wide & mighty strut-braced wings between normal airport gates, at an impressive 52m of span for a narrowbody airliner.

This is, of course, a problem.

The X-66A is intended to have folding wings, and Boeing is hardly new to this approach, with such aircraft as the F/A-18 naval fighter in it’s stable, but it’s not necessarily ideal: Structurally rigid hinged wings add a great deal of weight that you don’t want in a super-efficient technology demonstrator, which counteracts the drag reduction.

Fortunately, there is a solution to this too, and to describe this we shall take a quick trip over the Atlantic to France, and Boeing’s main competitor…

5: Inspired by the bird: Albatross-One

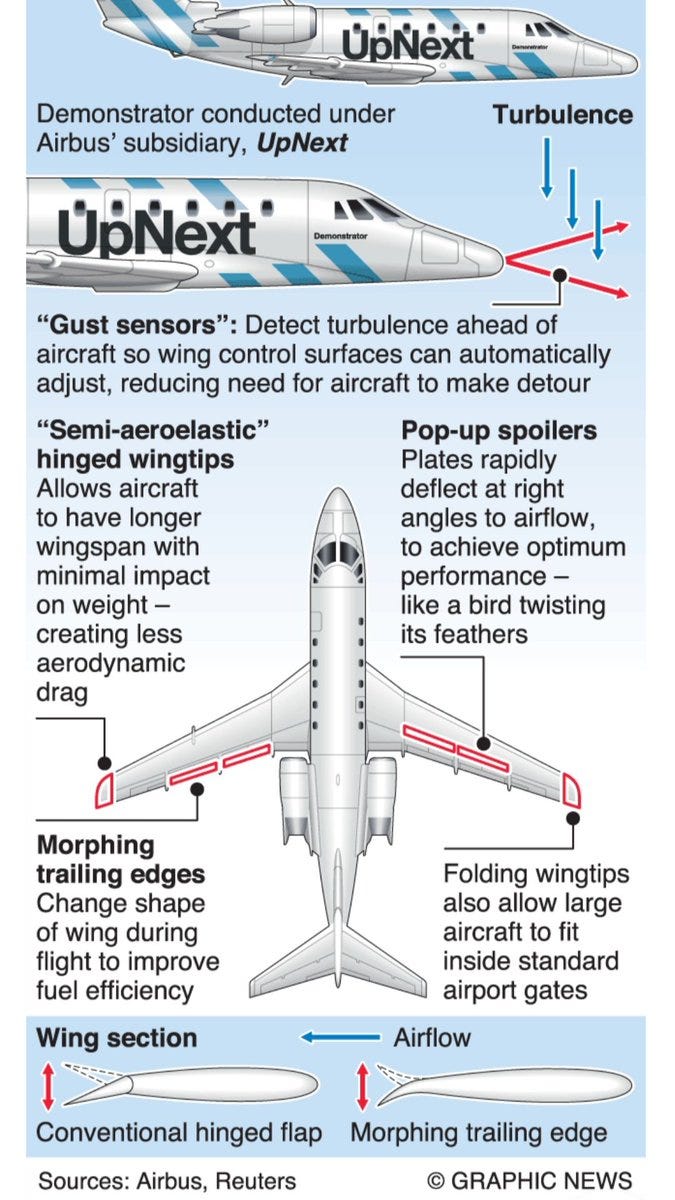

Airbus has its own innovative skunkworks-organization aiming at strange new concepts, and it’s called UpNext: They are better with aeroplanes than with names.

The high aspect ratio wing problem is one that UpNext has been looking at too, just like Boeing, though they’ve not gone as far as their American rivals with the strut-braced transonic wing concepts, preferring for now to stick with cantilever wings, and explore how to extend them safely.

A particularly vigorous period of rapid prototyping on the wide-wing problem led to the creation of the Albatross-One, a radio controlled miniature aircraft with an impressive wingspan and a feature directly inspired by the albatross itself: A semi-aeroelastic hinge.

Or, to put it another way, a wing tip that can flap.

The semi-aeroelastic hinge is a compromise that allows an aircraft to make use of super high aspect ratio wings, foldable wingtips and keep its wing structure from getting too heavy. Let’s look for a second how the bird itself does it.

The albatross, nature’s elite long distance specialist, has special tendons that lock in place while it’s soaring to reduce energy loss, but that unlock to allow it to flap and manoeuvre. UpNext’s Albatross-One mimicked that by using a lifting mechanism and a clutch to move the wingtips to preset positions or de-clutch and allow to flap freely. This sounds completely mental, but flight testing showed that a freely flapping wing gives good gust response, helps to damp moments on the main wing and so allows Airbus to qualify a hinged wingtip that isn’t fully rigid, since it’s designed to de-clutch and flap under heavy manoeuvre. The fact that it damps the entire wing during gust response and also adds a level of roll damping could potentially help reduce weight by changing the inputs to fatigue life estimation as well, though that last bit is mostly supposition.

In any case, it allows a super wide, super-efficient but still light wing to be folded away for airport gates. Cunning.

An interesting package of different technologies are aligning on this concept, so we’re in for interesting times. Furthermore this isn’t a paperwork exercise; there’s real hardware under construction, right now.

6: The Prototypes

Early last year Boeing took delivery of an old MD-90 airliner with the aim of transforming it into the X-66A, which after a battery of concept designs and evolving wind tunnel tests is now ready for the big time. We should expect to see the X-66A fly later this decade, depending of course on the resources Boeing chooses to throw at this project. The expectation is that the novel wing on it’s own will add some 10% of fuel efficiency to the overall design. This, by the way, is equivalent to a straight decade of improvements to aerospace powerplants, which tend to tick onwards at about 1% of improvements per year on average.

And, by NASA & Boeing’s estimation, depending on the mix of new technologies it’s partnered with, which may include hybrid power trains, high efficiency geared engines and other wonders, the full package may hit a 30% fuel efficiency improvement. That’s huge!

Meanwhile the competition is not sleeping: Stirred by the successful small scale trials of Albatross-One and other projects, Airbus’ incubator UpNext has taken delivery of a Cessna Citation business jet, which is to be converted into the eXtra Performance Wing demonstrator around the same time, with intelligent control surface morphing and, of course, flappy wingtips.

That’s some real excitement for us all! Airbus & Boeing going up against each other in a Battle Of The Big Wings: The strut-braced American against a wing-morphing European trickster.

…Which wing will win? I couldn’t resist.

It’s a show we can all look forward to, because whichever one wins, we all do.

Stand aside, Musk! The Buck Rogers approach to space

This week we saw yet another tumultuous re-launch of Elon Musk’s big Martian dream. A launch of the largest rocket in the world which led us to a small amount of iteration and a large amount of explosion. Try, try again.

Credit for images goes to NASA, Boeing, Airbus, Wikipedia and the paper Update On AlbatrossONE Semi Aeroelastic Hinge Small Scale Flying Demonstrator Project (Thomas Wilson).