Bootstrapping Icarus: Why rockets are hard

Icarus, pyrotechnics and a thousand tons of burning methane.

With a rumble heard across horizons, German company Isar Aerospace let loose a rocket to space this weekend from the frigid coast of Norway. It didn't quite make it. It was to be the first orbital rocket ever launched from continental European soil, and despite its untimely destruction a few seconds after clearing the pad, it is was a welcome first try: In a world where private access to space has been dominated by a single innovative company at the other side of the Atlantic, a flock of competitors now claw at the heavens. There will be more.

There is a joyful naïveté about rocket engines. From the outside it's all hot-stuff-comes-out, motive-power-happens, as the air itself shudders to an alien snare-drum, and everyone goes home smiling. “I understand that!” we think to ourselves.

But we don't. We really, really don't.

I think I understand the Mona Lisa too: Attractive woman with pleasant smile, brown aspect, paint. What's not to get?

Exactly.

I'm not going to tell you how to paint the Mona Lisa, but in this article I'm going to tell you what the colour brown is. In short, we're going to talk about our favourite solution for slinging heavy stuff into orbit around our planet: The liquid fuelled rocket engine, its many different varieties and what makes them a bit… tricky.

Light the blue touch paper and stand well back, because here we go!

1: The virtue of haste.

We'll start at the basics, but first in classic flash-forward fashion, we'll take a brief puzzling glimpse at the chaotic finale. Here it is:

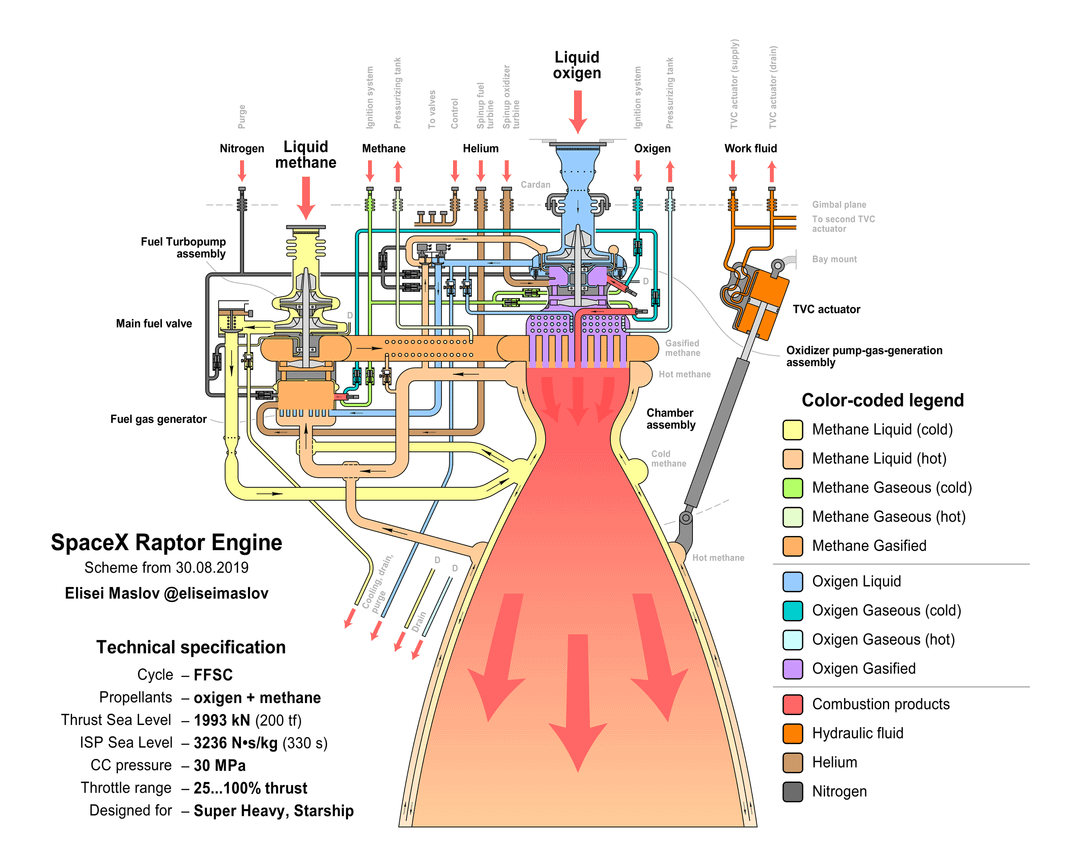

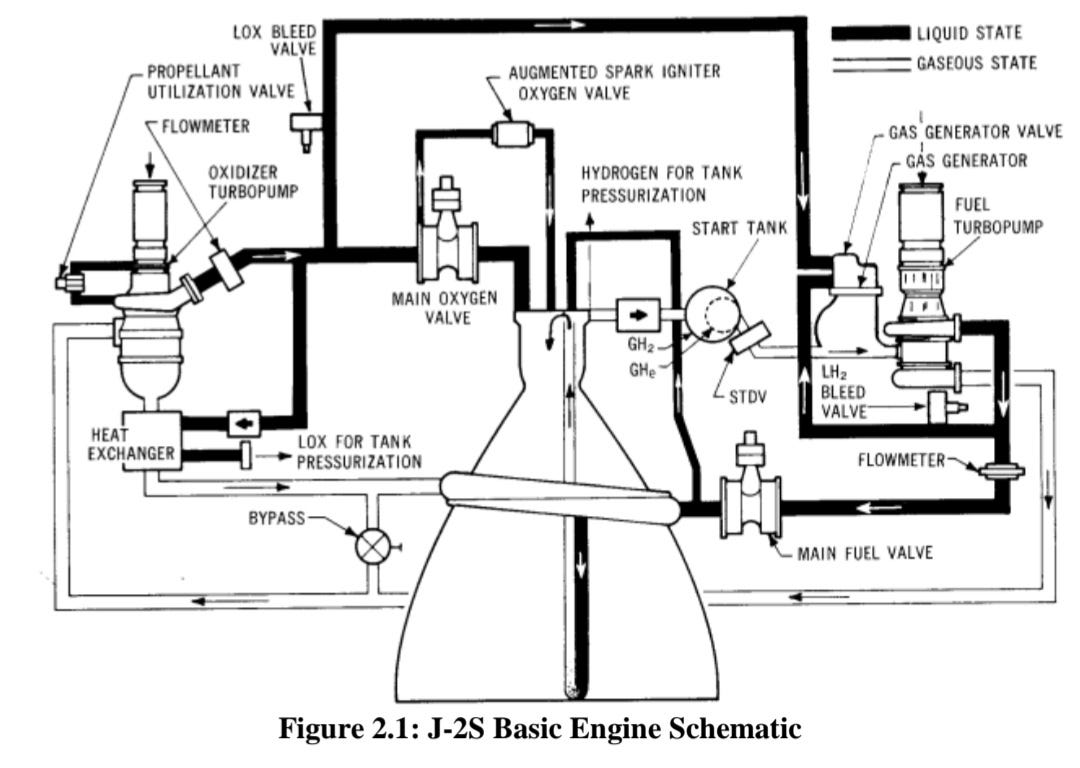

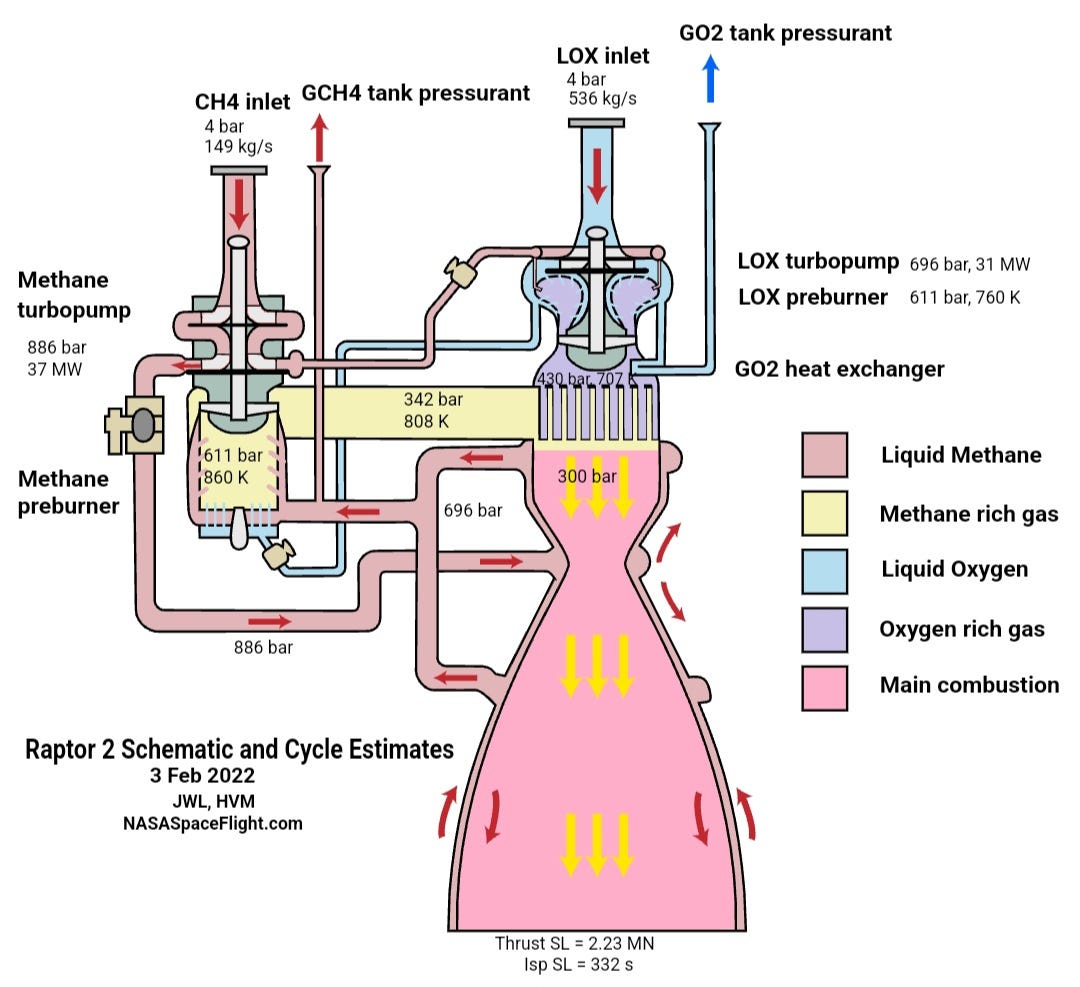

This colourful diagram is a full flow staged combustion methane-oxygen rocket engine. Take a deep breath now and skip the next paragraph if you're headache-prone, because how it works is…

Liquid oxygen and liquid methane at 4 bar (4 atmospheres of pressure) are run through separate turbopumps, boosting them to hundreds of bar. Each feed is then partially tapped and crossed over into separate preburners: A fuel rich preburner for the methane stream and an oxygen rich one for the oxy stream, hugely increasing the thermal energy in each stream, each of which are still mostly unburnt fuel and oxygen respectively. These streams then pass through turbines to power the turbopumps that got them to these outrageous pressures in the first place, before combining in the combustion chamber. Here they are burnt and expanded through a convergent-divergent nozzle, producing the thrust for the rocket. The nozzle itself is then cooled by the same high-pressure liquid methane stream from earlier, and a small quantity of each super-pressurised gaseous fuel and oxygen stream is directed back the the liquid tanks they came from to fill the ullage space.

Got that? You shouldn't! It's bloody ridiculous, but if by some chance you knew & understood all of that then you can pour yourself something nice, sit back and coast smugly through the rest of this. For the rest of us, we'll get our field glasses and take the scenic route, for by the end of this article it'll all make perfect sense. Let's start at the basics.

A rocket combines fuel & oxidiser for combustion and expansion through a nozzle that's designed to accelerate the exhaust: The faster the resulting exhaust, the more thrust you get for a given volume of fuel. For a rocket designed to reach orbit the fuel is usually liquid; methane, hydrogen or kerosene, all with their own pros & cons. For an oxidiser liquid oxygen is usually used, but alternatives like hydrogen peroxide are usable too. The oxidiser is carried because a rocket is not generally air-breathing and can't snaffle atmospheric air like, say, a gas turbine engine.

OK, so propellant goes out, fast, and you get a forward reaction, from kid's water rockets to the Space Shuttle and everything in-between. Good, but there are some subtleties it's important to know when talking about fuels, nozzles and pressures. One of these is the sheer overwhelming importance of exhaust velocity.

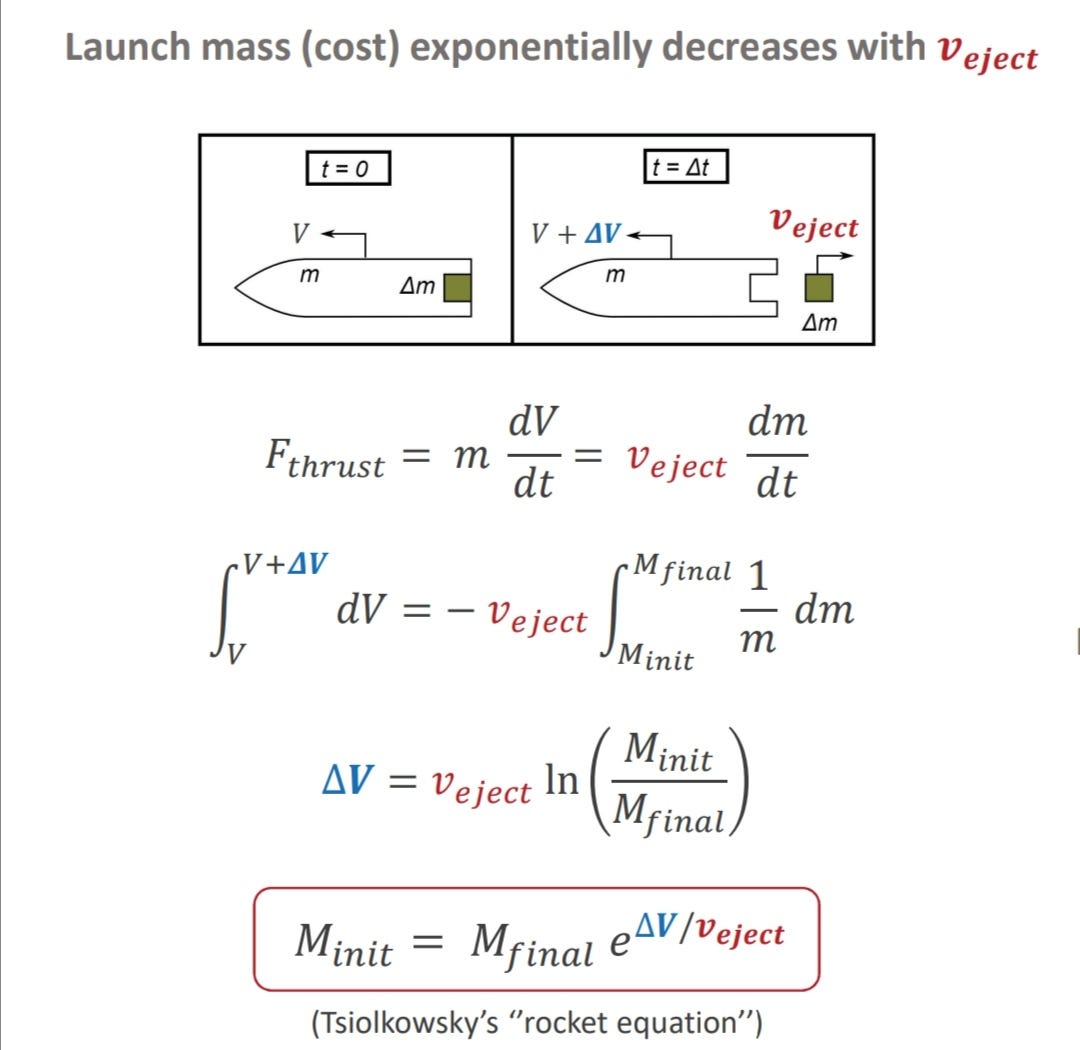

Here's the Tsiolkowsky rocket equation. Don't sweat the details, but the important thing is that it relates the mass of propellant required to change the velocity of a rocket to the speed at which that propellant leaves the exhaust nozzle. The key thing to realise is that the propellant mass needed increases in an exponential, not a linear, basis with the increase in rocket velocity. This means that when the velocity change is very high, because you're going into space and need to exceed 7.8km/s, you're going to need a rocket that is almost all propellant. A Falcon 9 rocket, for example, weighs about 400 tons fully-fuelled on the launchpad, but can get only about 17.5 tons max to low Earth orbit, or about 2% of the overall mass.

So remember that exponential function: The exhaust velocity is insanely important!

How do we get it?

2: Fuels, nozzles and the need to squeeze.

First we should disregard the insane: If exhaust velocity is all-important, why not max it out? That would involve an electric propulsion solution like a Hall Thruster, which accelerates Xenon in an electric field to a velocity of about 15-80 km/s, which is just crazy, and inspires similarly crazy fuel efficiencies in a spacecraft. Could we just launch stuff into orbit with them?

No we could not, because the actual thrust produced by these engines is miniscule, so an electric propulsion rocket would just sit on the launchpad, ineffectually puffing out xenon like a cyberpunk opium addict.

Perhaps solid fuels, then, such as the massive boosters that straddled the Space Shuttle back in the day? They certainly have a high thrust to weight ratio and are simple, stable and easy to store, but their heavy, complex exhaust products and solid particulates lead to a slow exhaust and low efficiency.

So we're at liquid fuels as the golden compromise for hauling heavy kit to orbit and beyond: Whatever science fiction solution you favour for the off-world colonies of your imagination, they'll need fuel tanks that slosh.

Once you've burned your fuel & oxidiser you need to accelerate them, and to do this requires a nozzle, which comes with a distinctive pinched-bell shape: The convergent section of the nozzle accelerates subsonic exhaust flow until it reaches the local speed of sound around the throat of the nozzle, at which point the rules are inverted and you must expand the duct in order to accelerate it further.

A quick aside: We've all seen these attractive diamond shapes in rocket or afterburner exhausts. This is what happens when your exhaust is in atmosphere and either over-expanded (the static pressure drops below local atmospheric) or under-expanded. It's a sign, in essence, that efficiency has been left on the table, but it's not practical to morph the geometry of a rocket nozzle to fine-tune it to local conditions, so we're stuck looking at diamonds.

And once a rocket reaches space the local pressure is basically zero, so it makes sense for a vacuum-optimised nozzle to be… really big.

And when you run the math, it becomes obvious that past a point increasing the combustion pressure inside a rocket, while it may increase raw power, does little for fuel efficiency. Nozzle diameter, on the other hand, matters a lot!

Nozzles matter.

What about fuel? If you remember from earlier, exhaust velocity is a big deal, so are some fuels better than others?

Yes.

Most orbital rockets will choose one of three fuel & oxidiser combinations: Methalox (methane-oxygen), hydrolox (hydrogen-oxygen) or keralox (kerosene-oxygen): I know, inventive names, but one thing that's immediately obvious is that one of these is very different from the others.

Hydrogen fuel allows for a max specific impulse (read “fuel efficiency”) about 25% higher than methalox or keralox, achieved at a very different and much leaner fuel/ oxygen mix. The reason for this is that the carbon-free wonder fuel that is hydrogen emits only water in its exhaust stream, with a substantially lower molecular weight than the more carbon-intensive output of either methane or kerosene. A lower molecular weight at a given temperature translates to higher molecular velocity, higher exhaust velocity and so higher efficiency.

Great, lovely. So why isn't hydrogen used everywhere? It was good enough for the Space Shuttle, the Delta IV Heavy and Ariane 5 after all.

And the blunt answer is that it's a pain in the arse to manage: Hydrogen liquifies at about 20 degrees above absolute zero, which is a massive 70 degrees colder than liquid oxygen, 90 degrees colder than liquid methane and hundreds of degrees colder than kerosene, which is liquid at room temperature. It's also a pain to store, pissing through all but the very best seals, needs lots more insulation and is a lot more expensive than the other two fuels.

Remember the orbiters listed above: Delta IV Heavy, Ariane 5 and Shuttle all required massive delta-V (velocity change) reserves for deep space or unconventional launch profiles. Hydrogen is good at this, but for low orbit it's mostly too much of a hassle.

But whatever the fuel you choose, you need to compress it, convert it from liquid to gas and burn it, and this is where rocketry gets really complicated.

Let's spin her up…

3: Pumping Problems.

You first need to get the fuel & oxidiser to the combustion chamber, and you need to do this at a high rate. One way is of course to pull inspiration from our childhood bottle rockets and just pressurise the propellant tanks: This can be done either by using an external pressure source such as helium bottles or else by decomposition or vaporisation of the liquid fuels themselves. Both methods, however, mean that you are ultimately limited by the structural integrity of your tanks, and the flowrate you can achieve just isn't that high. OK for simple vacuum rockets or manoeuvre thrusters, but you wouldn't want to rely on it to lift you off the launchpad.

A liquid rocket boost stage needs to pump fuel and cryogenic oxidiser to the combustion chamber at a rate that beggars belief: The 33 engines on the boost stage of SpaceX's monstrous ‘Superheavy’ booster each chew through about 700 kg of propellant every second. Put all those engines together and the flow rate of liquid fuel & oxygen would be sufficient to empty an Olympic swimming pool in under 2 minutes, if you could find an Olympic swimming pool for cryogenic propellant.

Can you think of any conventional lightweight pump that can do this? Me neither.

You need something special…

4: Turbopump Troubles.

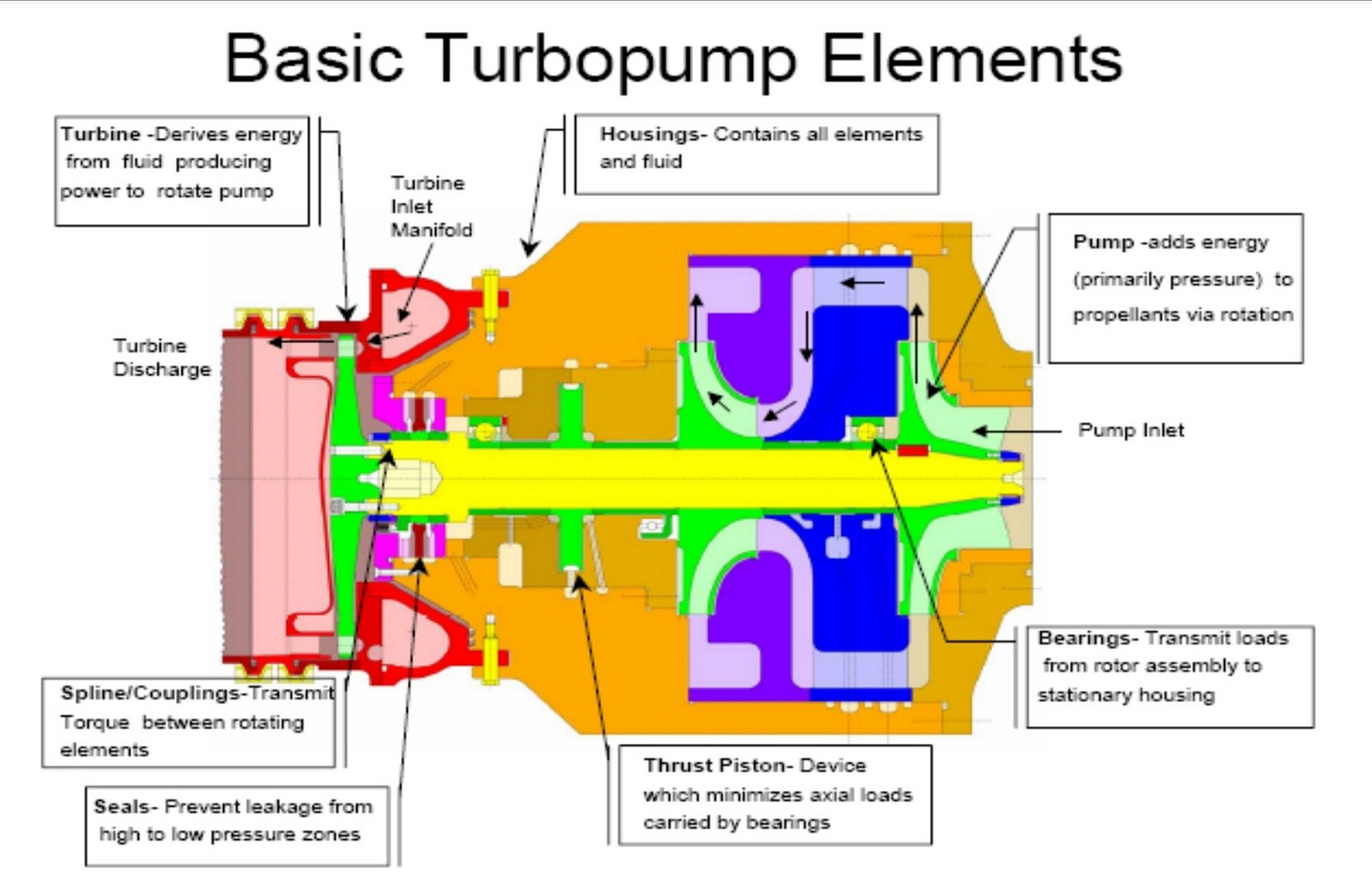

As ever, it's turbomachinery that rides to the rescue!

The turbopump comprises a typically-axial turbine powered by hot, pressurised gas flow that powers centrifugal compressor pumps that pump the colossal quantities of propellant required and pressurize it to, potentially, hundreds of standard atmospheres.

It's a handy, lightweight way to provide pumping power, but it does require that you have a source of hot, high-pressure gas to work with.

Now, where would you find that in a rocket engine?

Indeed. In order to burn fuel, we must pump it. In order to pump it, we may have to burn some of it.

Um…

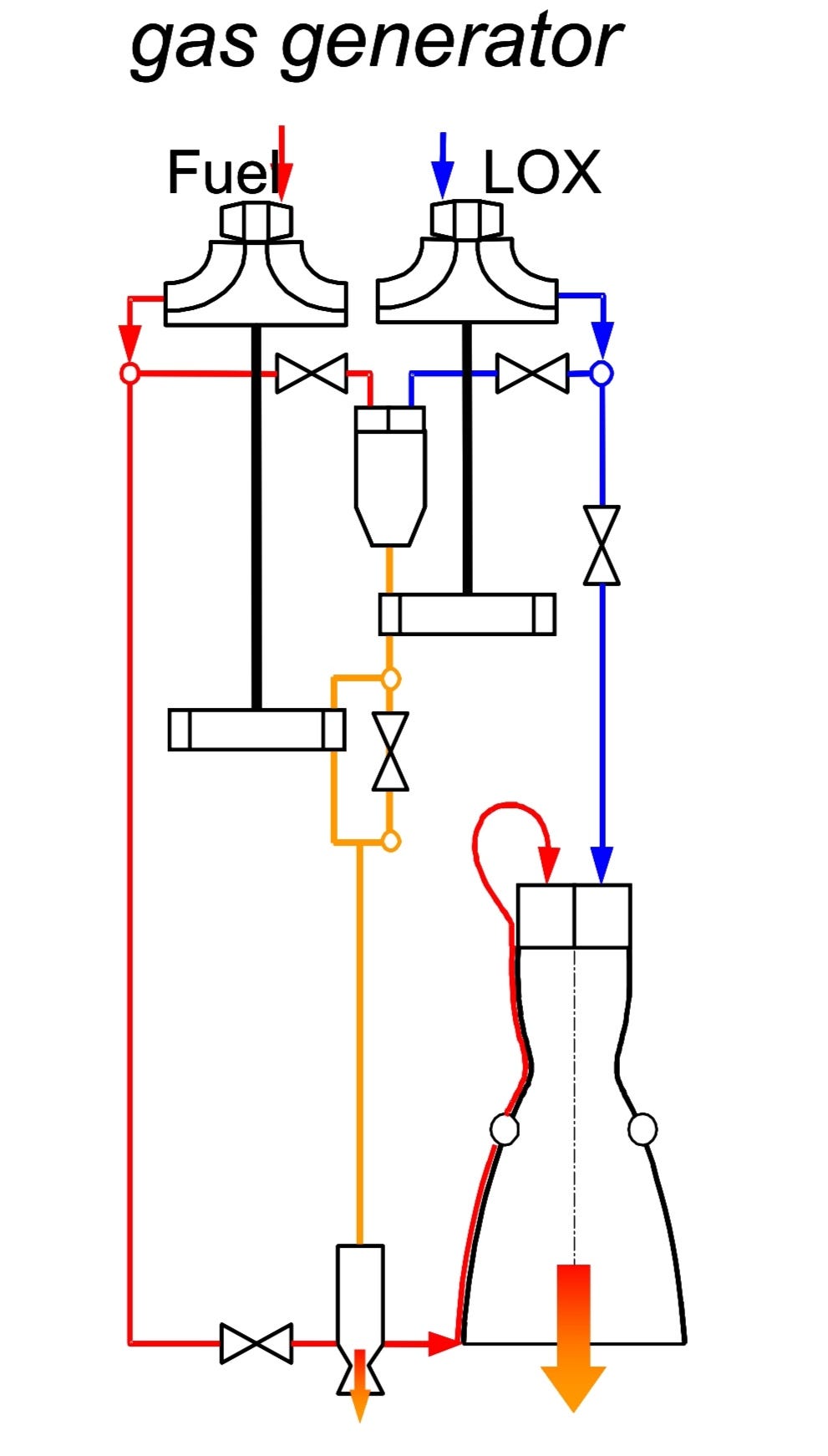

5: The Gas Generator Cycle.

A simple, robust solution to the above is pretty much exactly that: A small quantity of the pressurised fuel & oxidiser flows are tapped, brought to a small combustor, vaporised, ignited then expanded through a turbine that powers the fuel and oxygen compressor cycles.

Inevitably the gas generator can't run with a completely nominal fuel:oxy mix, as it would get so hot that it would melt the turbine blades, so typically a gas generator will trade off some efficiency and run fuel rich to power the turbopumps.

-Why not oxy rich? Because fuel has a higher specific heat at constant pressure (Cp) and so you need less mass flow through the gas generator if it's fuel rich than oxy rich, meaning more useful propellant goes to the main combustor & nozzle that moves the rocket.

So the upside of a gas generator cycle is relative simplicity and robustness, which is why it's used on the most reliable rocket motors around, the SpaceX Merlin. The downside is that you trade away efficiency by throwing away some of your propellant, meaning that the tyranny of the Tsiolkowsky rocket equation will kick you where the sun don't shine.

Is there a better way?

6: The Combustion Tap-Off Cycle.

Definitely found under the heading “a good idea in theory”, this cycle relies on tapping off a small portion of the hot pressurised gas from the rocket's main combustion chamber to power the turbine for the turbopumps. This would eliminate the need for a gas generator and could bring simplicity to the cycle, but sadly relies on tapping gas that was already burned close to its stoichiometric ideal and is therefore hot as all hell.

Remember that in the gas generator cycle above you need to burn fuel rich to keep the temperature down? Well in combustion tap-off you have much less control over that, so you're stuck with the need to make your turbine resilient to extreme temperatures, which is such a challenge that only two engines have ever attempted it, the Rocketdyne J2S and the Blue Origin BE-3PM, of which only the BE-3PM has flown.

However there are advantages: For one, the combustion tap-off cycle is relatively simple, which brings potential efficiency benefits. Secondly, the simple tap-off cycle has the ability to go into ‘idle mode’, where thrust is much lower than maximum, and to operate in a stable fashion across a wide range of thrust outputs, making it a throttleable rocket design. This is particularly useful for reusable rocket designs, which is one reason why Blue Origin favoured it for the BE-3PM on the New Shepard suborbital space tourism vehicle, where the hydrolox fuelled booster must descend and land under its own power.

To give some idea of the range of this, the well-tested but never flown J2S could run at an idle mode of 5,000 pounds thrust with a hydrogen oxy:fuel mix of 2.5, versus its maximum thrust condition of 256,000 pounds thrust with a mixture ratio of 5.5, meaning that it could throttle down to 2% of maximum thrust.

The BE-3PM can throttle from 110,000 pounds thrust to 20,000 which is not quite as ambitious but more than enough for a reusable booster stage, for it to make a powered decent and landing.

So: Tap-off cycles are tricky, but bring niche benefits. What other cycles are there?

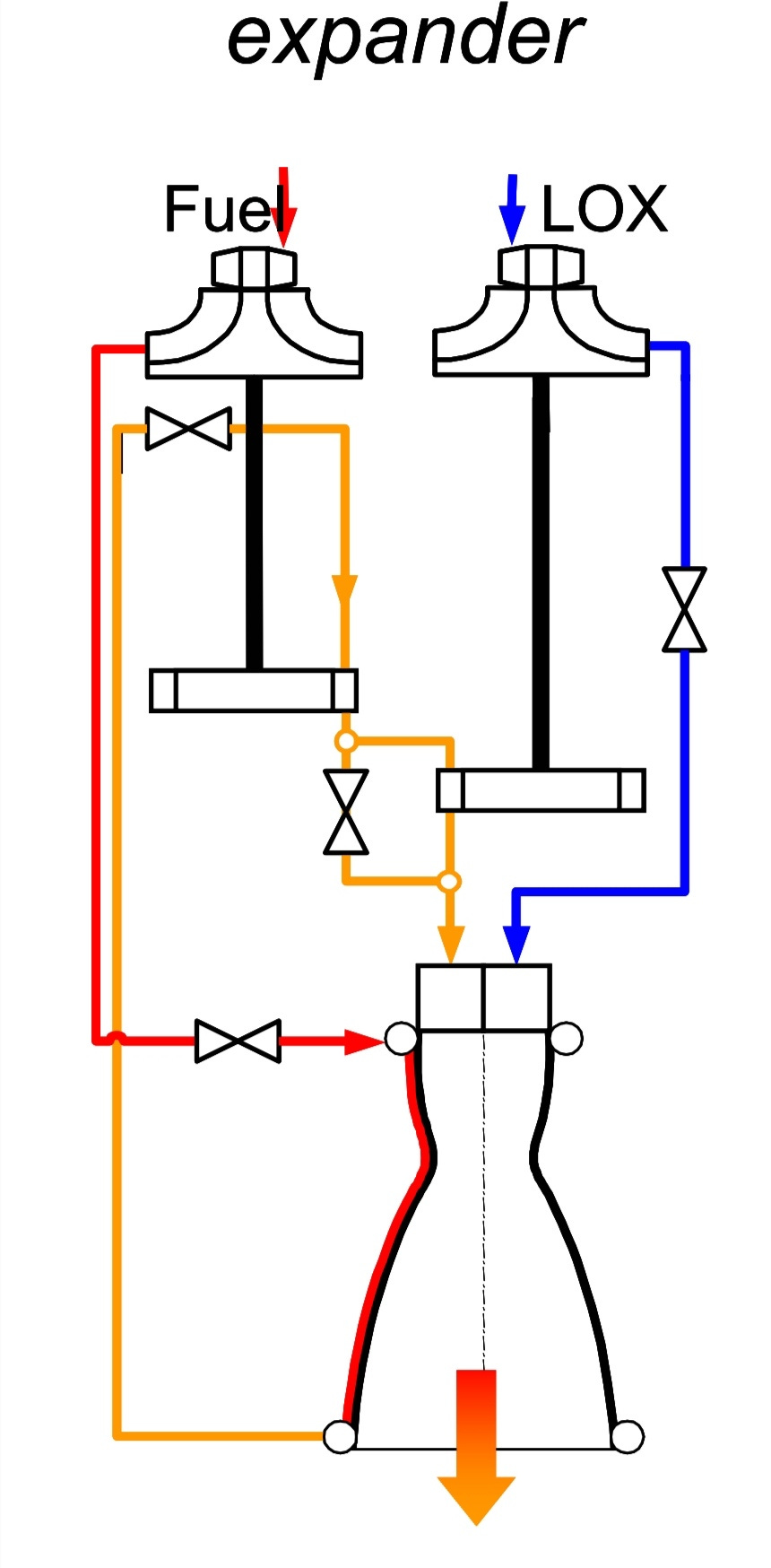

7: Heat recycling: The expander cycles.

A large liquid rocket's combustion chamber and nozzle is an environment like nothing else on Earth, which must be continuously cooled to prevent it from slagging itself (more on that later). The genius of expander cycles is that they make the coolant run the turbopump operation too.

Run the cryogenic fuel around the nozzle and combustion chamber and you will cool the chamber walls, but you will also heat & maybe vapourize the fuel, adding sufficient enthalpy to let it expand through a turbine to power the turbopump that got it there in the first place.

All of the turbopump cycles have a strong chicken-&-egg aspect to them, but the expander cycle makes this insultingly obvious: You can't pump without a little heat, and you can't get hot without pumping.

OK, that came out wrong, but you know what I mean. To close the circle, some expander cycle rockets use a gas generator or similar means to kick-start the expander cycle and get the chamber & bell temperatures high enough for it to work.

The expander cycles comes in two flavours: Closed and open. The closed cycle loops gaseous fuel from the turbine into the combustion chamber and so makes use of a maximum amount of the available fuel flow for combustion. The flipside of this is that the turbine must work against the back-pressure of the combustion chamber itself, reducing its effectiveness.

By contrast, the open or ‘bleed’ expander cycle sacrifices a small amount of its fuel, which is unceremoniously spewed into the void, but in return eliminates turbine backpressure issues and lets the turbine be smaller with a lower flow rate. Bleed cycles, because they don't run most of the fuel through the turbine, also find it easier to run with higher combustion pressures and so a better nozzle expansion ratio: Good for vacuum performance. Closed expander cycles include the Vinci engine for the Ariane 6 upper stage, and open ‘bleed’ expanders include Blue Origin's BE-3U upper stage engine on its massive New Glenn reusable launcher.

Why would you use such a convoluted method of propellant pumping? Well for an upper stage it has plenty more punch than a pressure fed cycle, and it comes with robustness advantages: The wide flow paths compared to gas generators make it resilient to fuel contamination, and the low temperatures of the fuel gas running through the turbine compared to gas generator cycles makes it easier to create reusable turbine architectures. This is a feature you'll see later in this article as we move through the really exotic cycles.

8: Staged Combustion.

Think back to the gas generator cycle from earlier, one of the most common liquid rocket motor cycles for big launchers. It sacrifices some fuel & oxygen in the preburner to run the turbopumps, and like a hiker taking a pee off a windy cliff this sacrificial propellant is then pissed away into the slipstream, lost to whirling chaos.

Now, think back even harder: As you remember, a fundamental limitation of the gas generator cycle is that in order to keep the turbine alive and not reduce it to a gooey mess you need to burn either fuel or oxy-rich in the preburner to keep the temperature down. This means that we're leaving money on the table, because a fuel or oxy-rich exhaust is still usable propellant.

Why throw it into the void?

Staged combustion attempts to address this, by taking either a fuel rich or oxy rich preburner, operating at a much higher flow volume than a standard gas generator, and routing the hot gases that leave the turbine straight to the combustion chamber so that they're not lost. This not only increases the average propellant exhaust velocity (since none of it is lost) and therefore efficiency, but also allows a lower average temperature in the preburner and turbine, since there's a higher volume throughput instead.

On the flipside you must deal with hugely increased engineering complexity, an increased potential for feedback control problems between the different parts of the engine, and also a much higher pressure preburner, since it will still need to deliver high working pressures to the combustion chamber after the losses of the turbine and injectors.

The Soviets got there first, and some of their genius manifested in the Russian RD180 oxy-rich staged combustion engine, which was bought by the Americans and used in Atlas rockets for many years. Its unique oxy-rich staged combustion cycle was efficient but not without drawbacks, as high temperature gaseous oxygen is brutal to exposed metal surfaces, demanding an enamel coating on many parts of the engine.

American staged combustion engines, by contrast, favoured fuel rich preburners, the most famous of which were the massive RS-25 Space Shuttle main engines.

And it gets even more complex than that…

We return to where we started: The SpaceX Raptor engine. Leave it to Elon Musk to go for something really over the top. The Raptor engines used in his colossal Starship super heavy, 33 to each booster, aren't just satisfied with staged combustion but instead went for something called full-flow staged combustion.

Confused? I shall explain.

Instead of choosing either an oxy-rich or fuel-rich preburner in their staged combustion cycle, SpaceX said “screw it!” and went for both. Two turbopumps per engine with two preburners, one fuel-rich, one oxy-rich, each feeling through the pump turbines and into the combustion chamber for mixing and final ignition of the remaining propellant. Why such a propensity for complexity from a company that espouses simplicity? A few reasons, but increased control of fuel & oxy streams is likely to be a factor, along with the lower duty and temperature required on each preburner and turbine due to increased volume flow rate. This could feasibly help with re-usability.

It's certainly impressive, whichever way you look at it.

But all of this complexity is just pumping, remember. We still need to burn.

Next, fuel injection & ignition…

9: Mixing up all kinds o'trouble…

At this point the image below should be starting to make sense, but there's a little more we have to go through to close this window on rocketry: Propellant injection, ignition and bell cooling.

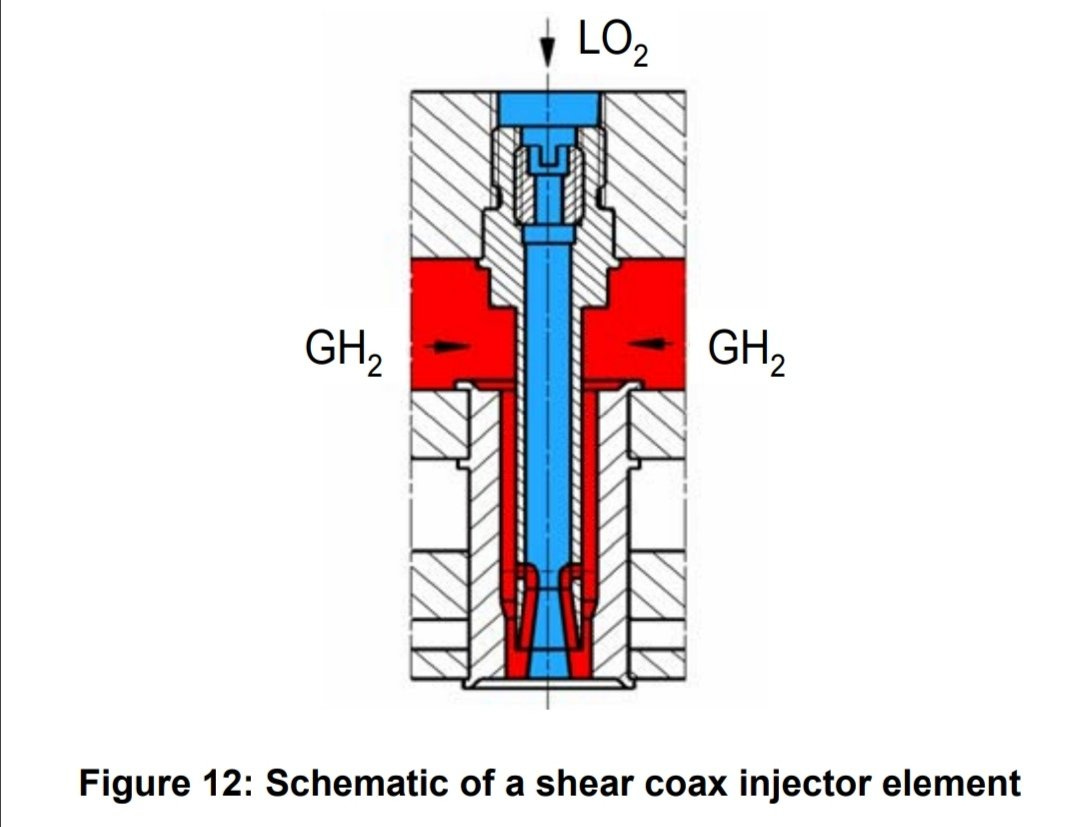

Pressurised liquid propellant needs mixing and atomizing before ignition: In some of the cycles above one or more propellant will be gaseous when it gets to the fuel injector. In any case, the separate oxygen and fuel streams have to be mixed quickly & uniformly before burning. The additional benefit of the injection system is that it should give some level of dynamic decoupling between the combustion chamber and the fuel feed: The need for this is obvious if you consider the dynamic nature of everything that has preceded this point. Were a combustion chamber's pressure fluctuations to start resonating with the fuel feed upstream, even a small amount of resonance could blow the rocket apart in short order.

Remember: There might be half a ton of propellant passing through every second, so a few hundredths of a second delay or instability carries tremendous force. We're dealing with some of the most energetic creations in the world of engineering.

An injector can act by impinging jets (particularly if both propellants are liquid), swirling flows or shear flows. A shear injector is shown, which works by generating turbulence in the mixing zone between the two fluids and is particularly common where one propellant is a gas.

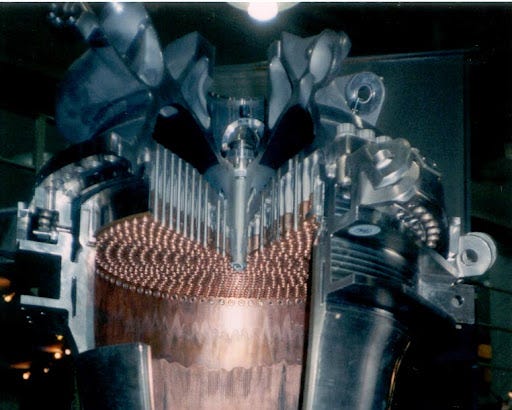

And while you're studying that, look at the injection zone of the Vulcain rocket engine: A porcupine's nightmare bride!

Injectors are precision-engineered and demanding: The pressure drop across the injectors can easily be 15%-20% of the combustion chamber pressure, so there's a real performance impact on getting the design right.

10: Hell’s Heart: Ignition & Cooling

So now you've got fuel and oxidiser in the right place, at the right pressures and appropriately mixed… but as in romance, so in rocketry: Nothing's going to happen without a spark.

You have one shot at this. Miss your mark by fractions of a second and hundreds of kilograms of propellant is going to be in the wrong place at the wrong time when it goes bang, which could mean a flameout… or the destruction of an engine… or a rocket… or a launch facility. God forbid someone's sat in it!

So ignition needs to be fast and dependable. It also needs to be smooth, with minimal pressure peaks and precisely timed, as with a high flow rocket even milliseconds of delay can create dangerous quantities of premixed propellant, ready to go off.

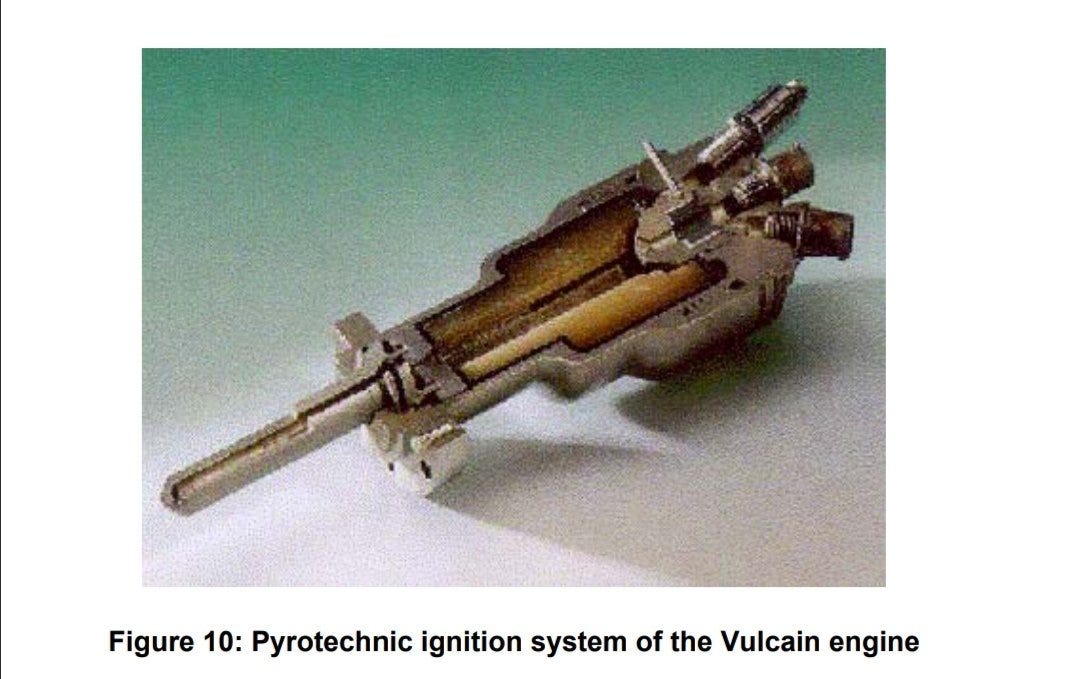

Our ignition choices are pyrotechnics, hypergolics and torches: Pyrotechnics are solid explosive charges, hypergolics are dissimilar chemicals which react energetically on contact and gas torches are self-explanatory. In all cases, they need to be designed, scaled and timed in concert with the dynamics of the injection & mixing system.

To design for this interaction requires an ignition probability map for a given configuration and injection rate. Firstly a mixing map must be created of the propellant within the combustion chamber, to which computational simulation is a huge asset to the designer. This is followed by the creation of a temperature map showing the effects of the ignition system on the combustion chamber flow environment, but without modelling chemical reactions. The product of these two then create an ignition probability map, which is necessary to assess different design configurations and the sequencing of injection and ignition on start-up.

But inevitably, computational simulation can only aid, not replace physical testing.

Sooner or later, you must expose metal to mayhem.

That brings us neatly onto cooling & wall interaction.

The wall of a liquid rocket's combustion chamber and nozzle must survive an environment that is beyond imagining, with temperatures of 3600K and heat transfer rates of 100 Megawatts per square metre (a ridiculous set of numbers). But the challenge isn't limited to heat: Where mixing is poor (such as near the walls) an oxygen rich environment can combine with cryogenic droplets hitting the walls, ‘blanching’ it in a combined physical and chemical attack. This can be fixed in a couple of ways: Either tweaking the injection ratio of injectors near the walls to reduce the gas temperature there, or else injection of a coolant film.

As well as thermal barrier coatings, crucial to anything that runs as hot as rocketry, there's the option of active cooling. We'll begin with regenerative cooling.

Regenerative cooling is the flow of pressurised cryofluid in channels beneath the chamber walls, to conduct away the worst of the heat into the fluid underneath. As we have seen, fuel is often used for this purpose. These channels can be tubes, which are lightweight but reach limits at pressures in the 100 bar region, or for higher pressure flows a ‘channel wall’ setup can be used, where highly conductive copper alloys are machined or formed into rectangular cooling channels.

Such cooling must take into consideration the change in behaviour of the coolant as it heats, and alterations to the heat flux it can manage as it moves around the chamber. This is a complex, iterative design area.

Another form of cooling is film cooling, where a quantity of propellant coolant is bled into the gas stream to create a barrier film. This is often used in addition to regenerative cooling, for the highest temperature regions.

Ablation cooling involves the sacrifice of an ablation layer, much like the re-entry thermal barrier on the Apollo capsules, which ablate away and create a protective gas barrier in so doing. This has the disadvantage of being a one-time only affair, not well suited for rocket re-use and not allowing significant changes to burn times.

A final method is radiative cooling, but this is primarily for smaller, lower heat flux engines operating outside the atmosphere.

So: We can pump, we can mix, ignite, burn and cool. In short, we have a working means of pushing a rocket forward… but as the booster-ballet of SpaceX has shown, returning rockets from space to the launch site in a delicate unfurling of landing legs, we need something a little extra in the 21st century.

We need to re-use our rockets.

11: The final frontier: Rapid Rocket Re-use.

How do you dip a complex machine into hell and expect it to keep going, again and again?

When you fire up a combustion chamber for the first time, one that makes use of cryofuels, there is a thermal shrinkage of exposed regenerative cooling fins, then a rapid expansion as the flame takes hold, creating enormous repetitive stresses. With plastic deformation exceeding 3 or 4 percent, a standard combustion chamber may only have 20 cycles of life in it.

Until recently, it might only need to work once. But expectations have changed…

This in itself, plus considerations of sooting and solid deposits, may explain why the current SpaceX Starship design leans heavily on both clean methane fuel, which produces no solid deposits, and full flow staged combustion, which reduces cyclic start-up thermal loads on combustion chamber linings.

Re-usability isn't just about catching a rocket. It's a root and branch engineering re-vamp that digs deep into a rocket's design genetics: Components get designed not for tens of cycles but for thousands. Long tail risk events loom larger and the space industry starts to morph over time.

As launchers get used more they become cheaper. As they become cheaper they get used more, and the industrial flywheel spins up… engineering chases customers who chase engineering again, and the entire enterprise becomes a little less Ad Astra and a little more Airbus.

Simplicity of use demands complexity behind the scenes. The market gets big and common, and without warning we're in a world where you're video-calling your kids over spring break. On the moon.

And slowly but surely, by the unseen labours of ten thousand engineers, the frontier of space becomes tamed.

But that doesn't mean that the adventure stops.

The Jet Engine: Secrets under the wing

We all know about jet engines: At least, we think we do, but familiarity has bred contempt, and there’s an entire world you probably don’t know about. Let’s dive into this murky, high-tech world of turbomachinery, and take a look at the future of humanity’s perfect heat engine.

Papers used in this article include Advanced Rocket Engines by Oskar J. Haidn